Friction is a given in car systems, as moving parts come in contact with each other. What keeps them from wearing out is lubrication. The oil creates a fluid barrier greases contact points, which prevents damage where there would otherwise be constant metal to metal friction contact.

That’s why sticking to your vehicle’s regular oil change schedule is a must if you want to prolong its lifespan. Without sufficient oil, the lubrication system can’t keep crucial parts of your vehicle moving efficiently.

What Is the Engine Lubrication System?

The lubrication system stores the oil in a sump, which is a low spot in the engine oil pan where the oil pump pickup tube and screen are, and distributes oil to different parts to ensure the smooth operation and longevity of a car’s internal combustion engine. While there is a pressurized oil feed through the oil gallery, splash oil lubricates parts that don’t require oil pressure for protection.

Parts of the Engine Lubrication System

To understand how the engine lubrication system works, it’s best to look at its parts and how they work. These include the oil sump, oil filter, oil pump, oil galleries, oil cooler, pickup tube, pressure relief valve, and oil pressure sensor or switch.

Oil Sump

The oil sump or oil pan acts as the reservoir where the oil sits when the engine is off. It also helps cool the heated oil that returns to it, though many engines have an engine oil cooler mounted somewhere in or on the engine or in/near the radiator.

The sump is basically the lowest part of the oil pan where the oil pickup tube is submerged. The oil drain plug is in the lowest part of the sump.

As the vehicle accelerates, brakes, or turns, the oil moves around in the pan. The pan baffles and oil pan shapes keep the oil pickup tube inlet under the oil.

As the crankshaft rotates, it churns and splashes the oil around, providing lubrication to components not requiring pressurized oil.

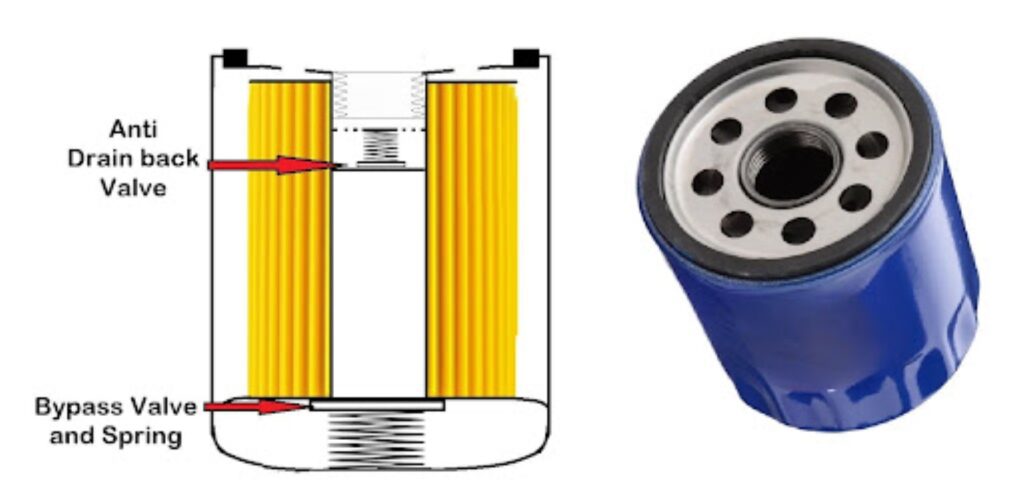

Oil Filter

There are two main types of oil filters: the full-flow/primary filter and the by-pass/secondary filter.

The full-flow filter regulates the oil without interrupting the flow, while the by-pass filter catches any contaminants the full-flow filter might have missed, acting as a secondary layer of defense.

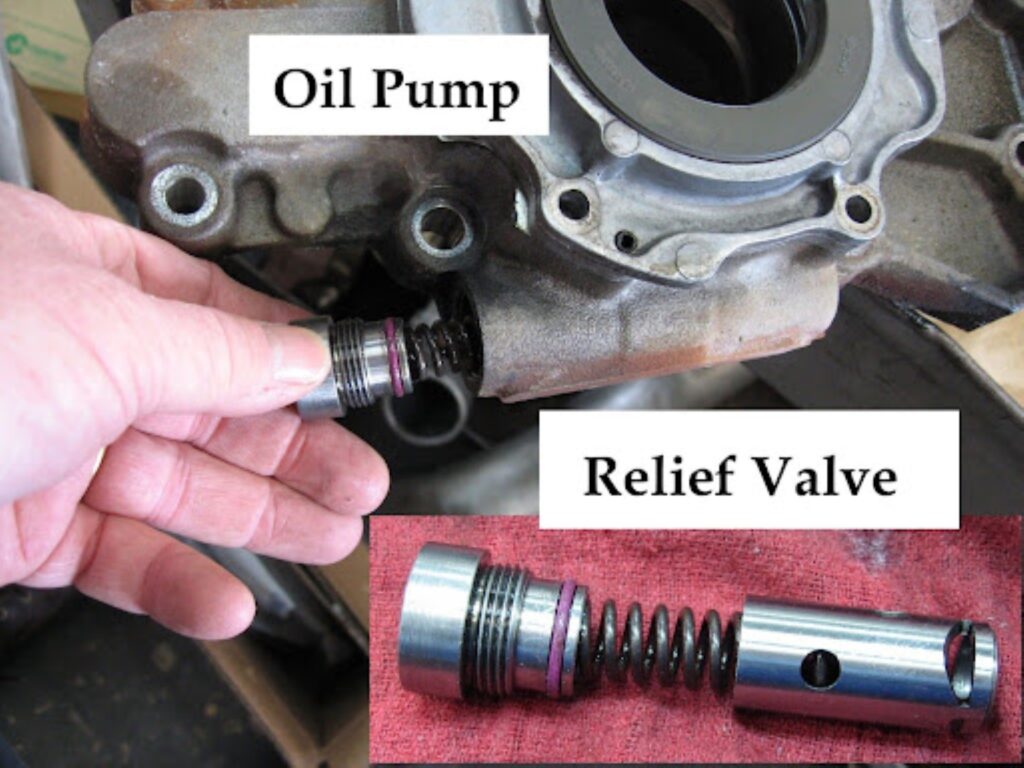

Oil Pump

The oil pump is the only component that receives oil not first passing through the oil filter. The oil pickup tube has a screen to keep large particles out of the oil pump.

The oil sump is the lowest part of the oil pan where the oil pickup tube is submerged. The oil drain plug is in the lowest part of the sump.

– Richard McCuistian, ASE Certified Master Automobile Technician

The pump uses two meshed gears to create the flow, while a rotor pump generates it by spinning rotors. There are four types of oil pump: the external gear type, internal/external gear type, rotor type, and gerotor type.

External Gear Type

The external gear type is usually driven by a shaft from the distributor, which is controlled by the camshaft, meaning gear types rotate at half-engine speed.

This pump also has two spur gears in a close-fit housing. When the pump is pumping, oil is carried around the outside of each gear in the space between the gear teeth and the housing.

Internal/External Gear Type

The crankshafts usually drive internal gear types and operate at engine speed. This type has two gears and a crescent stationary element.

Rotor Type

On the other hand, rotor-type oil pumps are driven by the crankshaft with a special lobe-shape gear meshing with the inside of a lobed rotor.

The center lobed section is driven, while the outer section idles. Oil is then drawn in when the lobes separate. Once the pump rotates, it carries oil around and between the lobes.

Gerotor Type

Gerotor, or Generated Rotorm, is a type of oil pump that uses an inner and outer rotor. The former has one fewer teeth than the latter, while simultaneously rotating.

Oil Galleries

The oil galleries are a series of interconnected passages that deliver the oil to the different engine components. They vary in size and are located inside the cylinder block, where bigger passages connect to smaller ones to supply oil up to the cylinder head and overhead camshafts.

Pickup Tube

The pickup tube draws the oil from the oil pan and delivers it to the oil pump before it passes through the galleries.

Oil Cooler

Some cars have an oil cooler that cools down the engine oil transferring some of the heat to the engine coolant through its fins. The oil cooler prevents overheating by either air cooling or liquid cooling the oil.

Throughout the cooling process, the oil maintains its normal viscosity level while retaining its lubricant quality.

This is important because excessive temperatures are harmful to the engine. Cold oil can be too thick to flow through the passages, which prevents lubrication. Meanwhile, hot oil can become too thin to provide the film strength necessary to prevent metal-to-metal contact and wear.

This is where a larger capacity oil pan comes in handy, as it can help control oil temperature. Some engines also have remote mounted oil coolers.

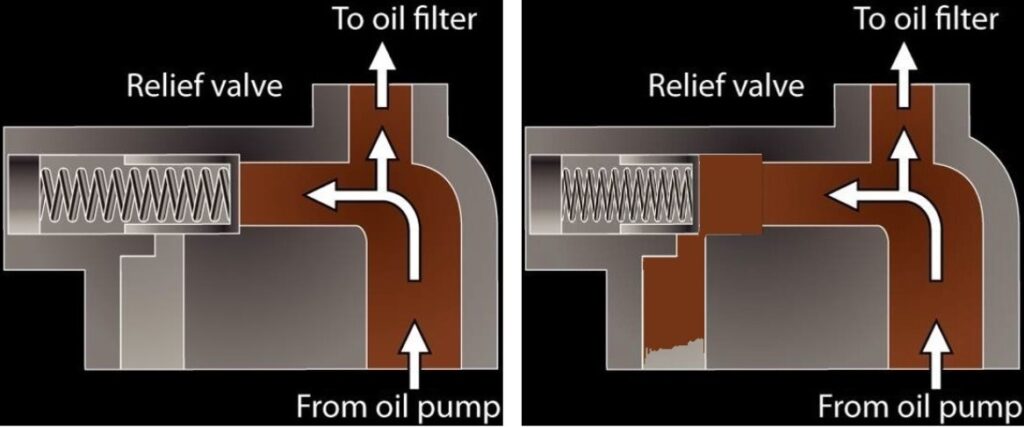

Pressure Relief Valve

The oil relief valve helps regulate the oil pressure within the system by opening and allowing excess oil to bypass back to the oil pan. It’s located in the oil pump or engine block.

As for the correct oil pressure, it should range from 10 to 60 psi or 10 psi per 1000 engine RPM. However, it’s also normal to see the following:

- Higher oil pressure when the engine is cold due to the oil being cold and at a higher viscosity.

- Lower oil pressure when the engine is at normal operating temperature due to the oil becoming thinner even though it is multi-viscosity oil.

- Lower oil pressures at idle and higher pressures at higher engine speeds because oil pumps are “positive displacement” pumps.

Oil Pressure Sensor

The oil pressure sensor keeps track of the oil pressure and sends signals to the engine control units (ECU) if the pressure is too low or too high.

Main Lubrication Points

The main lubrication points or the engine parts that get lubricated are the bearings, piston rings, cylinder walls, and valvetrain components.

Bearings

Types of Engine Lubrication System

There are three types of car engine lubrication systems, namely: splash, pressure, and dry-sump. They serve the same purpose, which is to store and deliver oil to different components but differ in how they do so.

Splash System

Splash lubrication systems splash oil onto the engine components using the rotating crankshaft or connecting rods. They’re typically used in small engines like lawnmowers or motorcycles. This system relies on the centrifugal force of rotating components to distribute the oil.

Splash lubrication isn’t as precise as other systems, as some parts are oiled too much or too little.

Pressure System

Pressure lubrication is often used in modern engines. It’s essentially the system discussed above.

As mentioned, pressure lubrication uses an oil pump that delivers oil to different components. It provides better control over oil flow and is more effective at delivering oil compared to splash lubrication.

Dry-Sump System

Lastly, dry sump lubrication stores the oil in a different tank or reservoir and uses multiple oil pumps to collect oil from the engine and send it to the tank.

This system is typically used in high-performance vehicles, like race cars, and allows for better oil control, reduced oil foaming, and improved oil cooling.

Engine Lubrication System Maintenance

The engine lubrication system needs maintenance, so the components are lubricated to keep them working at a high level.

You can maintain the system by changing your oil to ensure the components have fresh oil to avoid decreased performance and possible warping caused by friction between the parts.

As for the interval, it’s usually ideal to do it annually or every 3000 to 6000 miles, whichever comes first.

Get the Right Oil System Components for Your Vehicle

Maintaining your oil system is critical. Otherwise, your engine will rapidly deteriorate, as the lubrication system needs to continuously pump and filter oil. The most common components that need to be replaced in the oil system are the oil filter and oil pump. The former is consumable, while the latter can fail easily in some vehicles.

Whether you’re getting consumable parts like oil filters or vehicle-specific components like oil pumps, CarParts.com’s easy-to-navigate website can help you order online without trouble. You can check our extensive oil filter catalog with only a few quick clicks. You can even filter results to parts that are sure to fit your vehicle with our vehicle selector.

Keep your engine in tip-top shape with the right oil filter or oil pump. Buy replacement oil filters and oil pumps from CarParts.com today.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.