Note: Some relays are integral parts of the junction box or relay module and cannot be tested or replaced separately. This article only covers replaceable relays.

Relays are electronically operated switches that control power flow to a device. Relays allow the vehicle’s computer or the driver to control various vehicle electronics using small electric currents.

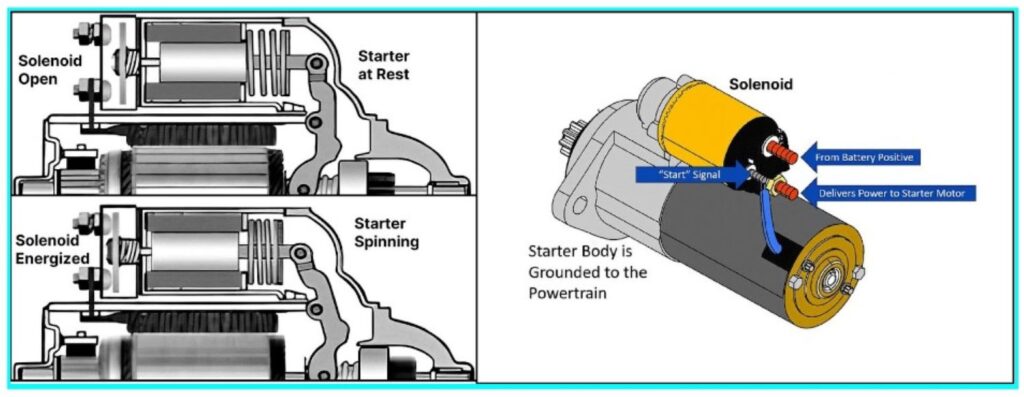

For example, the starter solenoid is, in effect, a heavy duty relay that is triggered by a small amount of current through a small switch and wire to close and carry a large amount of current from the battery directly into the starter motor. When the “start signal” is delivered to the solenoid windings, the core of the solenoid moves backward very suddenly, slamming a copper washer against the battery positive post and the starter motor feed post instantaneously.

Today’s starter solenoids are activated by a much smaller relay, so in that case, you have a small relay receiving commands from the PCM or ignition switch to energize a much larger relay.

Relays can also be used in pairs to reverse polarity of components like door lock actuators rather than having the actuators directly wired to the door switches.

Relays have an electrical winding with a non-moveable metal core so that when the winding is energized with power and ground, the metal core becomes a very strong magnet and pulls a lever inside the relay so that the contact point on the moveable lever quickly snaps against its non-moveable counterpart, and that set of points connect battery power to the load.

A faulty relay can prevent you or your vehicle’s computer from controlling devices like the vehicle’s air-conditioning, cooling fan, headlights, fuel pump, and starter motor, among many other components. The PCM and the fuel pump are also powered by relays, and so some relays can prevent the vehicle from even starting at all.

When a certain electronic part malfunctions, the relay associated with it is one of the first things to check. Sometimes, your vehicle might be showing symptoms of a faulty cooling fan or fuel pump, but the issue might just be a malfunctioning relay that corresponds to the faulty part. Hence, checking your vehicle’s relays is important when it comes to diagnosing issues. In this article, we’ll discuss how to test vehicle relays.

Preparing the Right Tools

You’ll need a multimeter, alligator clips, test leads, and a benchtop power supply or a 12V battery. The multimeter allows you to check the continuity between two separate points along an electrical circuit. Meanwhile, the 12V battery is meant to activate the electromagnet inside the vehicle relay, which can either establish or break the electric circuit that leads to the relay’s corresponding component.

Finding the Fuse Box

Relays can be found under the hood inside the fuse box or under the dashboard, depending on the relay you want to find.

You should refer to your vehicle’s owner’s manual because it will tell you where specific relays are located. That said, many vehicle relays like the ignition relay and fuel pump relay are located inside the fuse box, which is typically located under the hood.

Finding the Relay For a Device

Once you’ve found the relay for a specific device that you want to rest, you can pull it out with your fingers. However, gripping the relay can be difficult, as it’s typically wedged between other relays. You might want to use a tool like long-nose pliers to pull it out.

Switching To a New Relay

There’s an easy way to determine whether a relay is faulty. If a device like your vehicle’s headlights doesn’t function, simply replace the relay that corresponds to the headlights with one that you know is good and then check if they now work. If they do, then the relay is likely problematic.

Understanding the Relay Prongs

Vehicle relays typically have four or five metal prongs or pins. Relays have numbers that are printed or embossed to help you identify the function of the pins. Pins 85 and 86 are responsible for activating the relay’s electromagnet. When current flows between these two pins, they can either complete or close the circuit that powers the device.

Meanwhile, pins 87 and 30 are the switch pins. Pin 30 is typically connected to a power source like the vehicle’s battery and pin 87 is connected to the controlled device unless the relay is paired with another relay in a polarity reversal circuit.

In 5-pin relays, a relay could alternate power flow between two controlled devices. 87a would be a normally-closed pin and 87b would be normally open.

Listening for a Clicking Sound

Checking a relay involves connecting pins 85 and 86 to a battery or power source. As the circuit is completed, the relay should make an audible click that indicates that the electromagnet is working and is completing the circuit. If the relay doesn’t make an audible click, it might mean that the relay has stopped working and isn’t completing the circuit.

Doing a Resistance Test

You can also test your relay’s functionality by switching your multimeter to test for resistance. This process involves switching your multimeter to read ohms and connecting the two leads to pins 85 and 86.

A functioning relay coil should have a reading of between 50 and 120 ohms, but usually it’s very near 75 ohms. If it reads a lot higher or is open (“OL” on the DVOM), the coil is faulty and you’ll need a new relay. But again, even if the copper winding is good, the contacts can fail to carry a load.

A functioning relay coil should have a reading of between 50 and 120 ohms, but usually it’s very near 75 ohms. If it reads a lot higher or is open (“OL” on the DVOM), the coil is faulty and you’ll need a new relay. But again, even if the copper winding is good, the contacts can fail to carry a load.

–Richard McCuistian, ASE Certified Master Automobile Technician

Testing Switch Pin Continuity

Assuming the control pins are working, you can proceed to test the relay’s switch pins. The switch pins on a Normally Open (NO) circuit should have no continuity when not energized. Use a multimeter on the ohms setting to measure resistance between the switch pins. Any resistance indicates the pins are stuck closed, signaling a faulty relay. That being said, a DVOM doesn’t measure the relay contacts’ ability to carry current.

Once you’ve confirmed the relay’s integrity without power, it’s time to test its functionality when energized. Use a benchtop power supply, a 9-volt battery, or a 12-volt power source to energize the coil pins. This is typically 85 and 86 on a four-pin relay. Listen for an audible click as the electromagnetic coil activates and the internal switch closes. Switch your multimeter to continuity mode, listen for the audible beep, and test for continuity between the switch pins. If there’s no beep, it means the switch pins are stuck open and your relay is faulty.

Testing for Current and Voltage Delivery

It’s crucial to verify that the relay is healthy enough to deliver both voltage and current. But don’t trust a DVOM for this test. Always use a robust load like a motor or a headlamp bulb depending on the circuit the relay is carrying.

Find the Right Car Relay For Your Vehicle

Your vehicle has many different relay types, such as the main relay, starter relay, and A/C control relay. These parts aren’t interchangeable, so if a relay fails, you must replace it with the right item. Fortunately, CarParts.com makes it easy to find the specific type of relay that you need.

At CarParts.com, you can browse a wide selection of relays, including main relays, starter relays, and A/C control relays with no effort. Find the one that perfectly fits your application by entering the year, make, model, and engine of your car or truck into our website’s built-in vehicle selector. A few taps on your phone’s screen are all you need to place an order, and we deliver to your doorstep. If you live in the continental US and complete our ordering process by noon ET, your replacement relay can arrive in as little as two business days.

Choose from CarParts.com’s catalog of main relays, starter relays, A/C compressor relays, and other relays, and get a great deal today.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.