What Do the Crankshaft and Camshaft Do?

The crankshaft and camshaft work together to allow the engine to “breathe.” Here’s a breakdown of how the crankshaft and camshaft operate.

Camshaft Function and Operation

The main role of the camshaft is to control the opening and closing of valves during the combustion process.

The camshaft is geared to the crankshaft, either directly or with a chain or belt and it only spins half as fast as the crankshaft, which requires two full 360 degree rotations per cycle (720 degrees total).

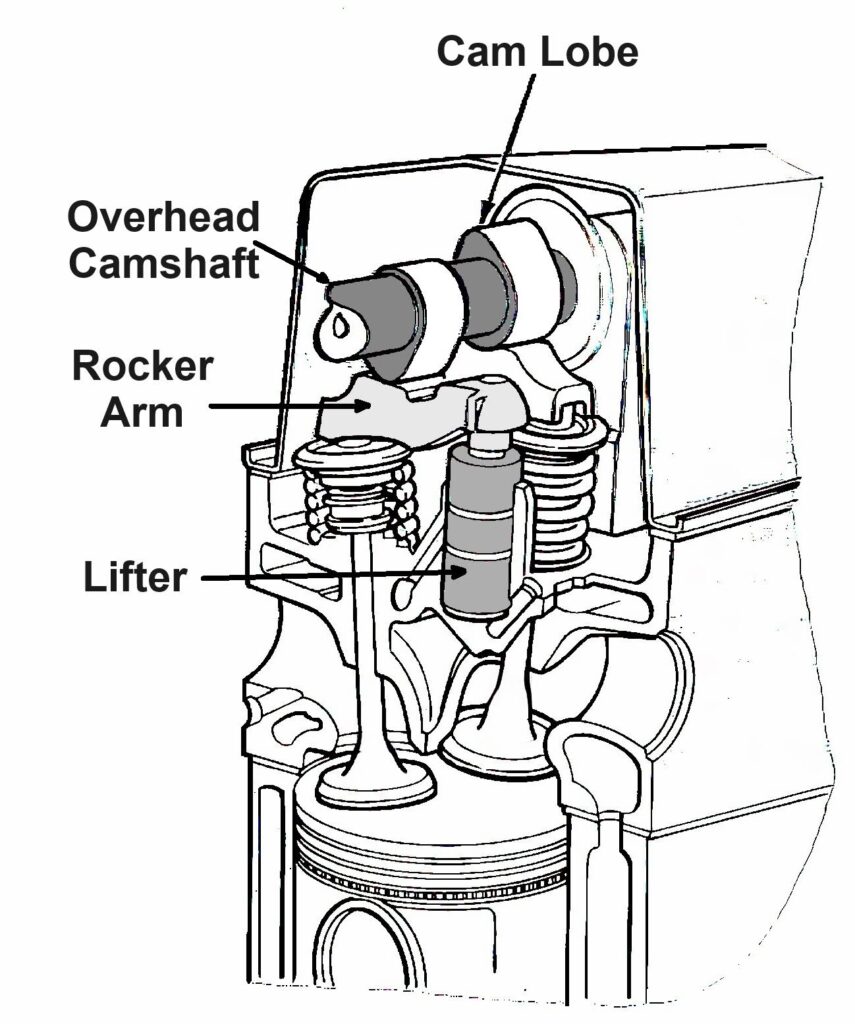

The camshaft can either be in the block with pushrods and rocker arms operating the valves or mounted overhead as shown in the illustration with roller rockers operating the valves.

While the camshaft is driven by the crankshaft, the crankshaft only provides power because the camshaft is operating the intake and exhaust valves in each cylinder to allow the engine to breathe.

As the camshaft rotates, its lobes open the valves against the force of the valve springs.

The lobe’s action changes the camshaft’s rotary motion to linear motion. In other words, the valves operated by the lobes only move in two directions: they open and they close.

In some vehicles, the camshaft is also responsible for operating the mechanical fuel pump, distributor, and oil pump.

Pro Tip: On gasoline direct injection (GDI) engines, for example, the camshaft also has a special set of lobes dedicated to operate the high-pressure fuel pump.

The backward and forward movement of the lifter generates an alternating torsion at each cam lobe, and the number of cam lobes on the shaft multiplies the alternating torsion force.

If you’ve ever turned a camshaft during the installation of a timing belt, you can feel this happening. The valve springs provide resistance that pulsates as the lobes pass their respective high spots. This causes camshafts that are directly geared to the crank gear to make a lot of noise unless a spring-loaded scissor gear or some other material besides metal is used for the cam gear teeth.

Crankshaft Function and Operation

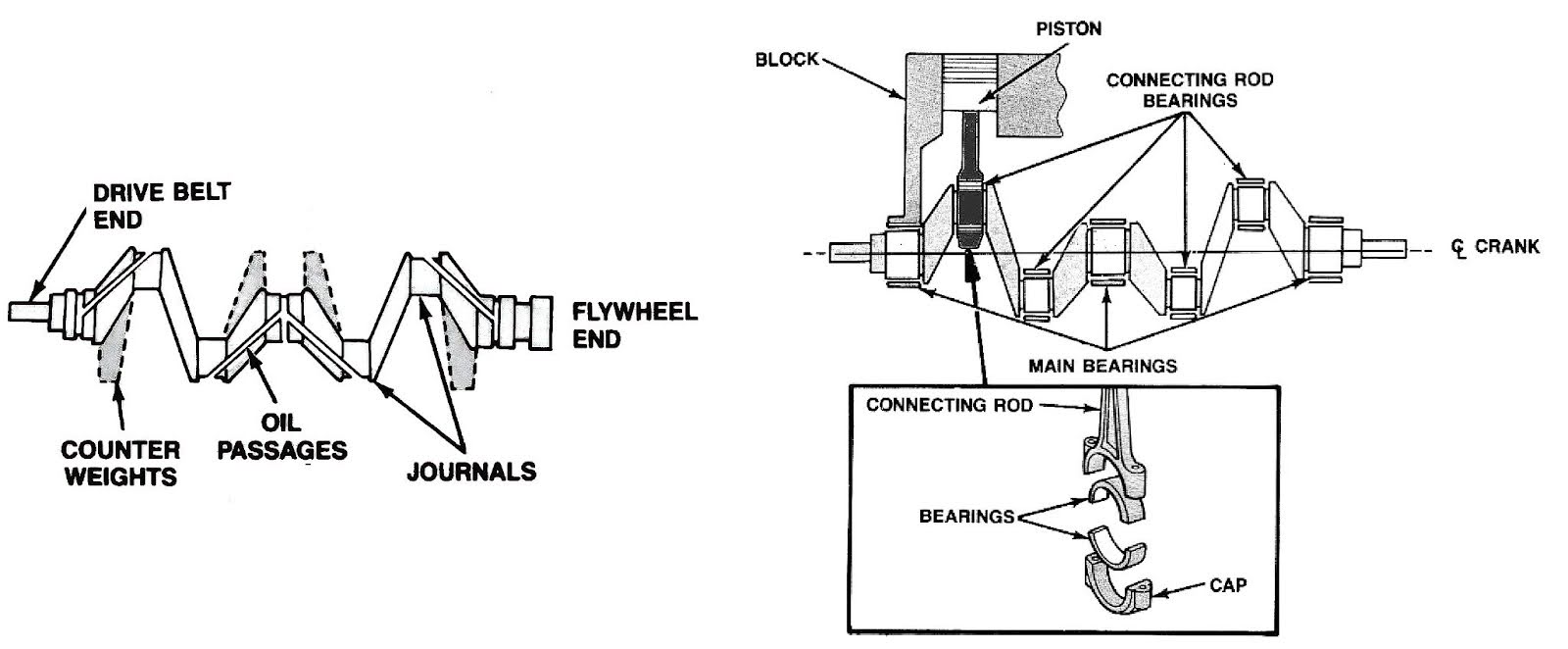

The crankshaft is a crank with a number of handles, and it has one crank throw for each piston and connecting rod. As with every crank, it is structured to do work as it is cranked.

A typical crankshaft has the following parts:

- Main bearing journals

- Rod bearing journals

- Crankshaft throws

- Counterweights

- Front snout

- Flywheel flange

- Keyways

- Oil passages

As the crankshaft rotates, it travels all the way to the bottom of the cylinder bore, with the connecting rod transferring that motion to the corresponding crank throw, which converts the piston’s vertical movement into a rotational motion, all driven by the combustion events that happen in sequence in the cylinders above the pistons.

The arrangement of crankshafts on engines can vary, depending on vehicle specifications. These types include:

- V-8 engine arrangement

- Four-cylinder engine crankshafts

- Five-cylinder engine crankshafts

- Three-cylinder engine crankshafts

- Inline six-cylinder engine crankshaft

- 90-degree V-6 engine crankshaft

- 6-degree V-6 engine crankshaft

Unlike camshafts, crankshafts can be forged, cast, or manufactured using a billet.

The crankshaft can fail after some time, but usually lasts the life of the vehicle unless the engine runs low on oil pressure for one reason or another.

Worn journals, scored bearing journals, bends or warpage, cracks, thread damage, and worn seal surfaces can render the crankshaft inoperable.

Crankshaft problems are bound to arise after some time, given that the stress on it increases by four times every time the engine speed doubles.

The crankshaft is also prone to vibration damage.

Every time combustion occurs, the force deflects the crankshaft as it transfers torque. Crankshaft deflections are a normal occurrence, and the crankshaft can often resonate with other vibrating parts.

Once these vibrations become great enough, you might hear a thumping sound. Keep in mind, however, that a consistent vibration loud enough for you to hear is a probable sign of a failing crankshaft.

What Is the Difference Between a Crankshaft and a Camshaft?

Bad Camshaft and Crankshaft Sensor Symptoms

Bad crankshaft symptoms can show up as low oil pressure and knocking. If the crankshaft breaks, the engine stops, and it usually warps the block so that it needs line boring.

The camshaft lobes can begin to round off so that they don’t provide the necessary lift. If a lobe is completely rounded off, machine-gun like popping noises may come back through the intake.

The crankshaft and camshaft have a sensor that monitors their position and speed. The crankshaft sensor provides ignition and fuel injection reference and the camshaft sensor provides cylinder identification and cam sensor indexing on engines with variable valve timing.

Pro Tip: On GDI engines, the cam sensor input is factored into the high pressure fuel pump’s pressure control solenoid cycle. The cam sensor tells the ECM exactly where the high pressure pump piston is while it is supplying high pressure fuel to the GDI rail.

The camshaft position sensor sends information about the camshaft’s position to the powertrain control module (PCM). This information lets the computer know which valve is open in a particular cylinder. On many platforms it tells the ECM when the piston has passed 24 degrees ATDC to green light the next injector event (even on MPI platforms).

By confirming that the valves are aligned for proper air and fuel delivery, the computer is able to determine the proper conditions for intake, compression, combustion, and exhaust activities. The cam sensor is also used for feedback on variable valve timing systems, which is one of the more important functions it has on modern engines.

On multi-point injection (MPI) engines with distributors or cam sensors mounted on a synchronizer where the distributor used to be, the cam sensor alignment must be set right. On these, a crank sensor triggers the ignition, and a scan tool is typically needed to index the distributor properly.

Pro Tip: You can’t change the ignition timing by turning the distributor on an engine that has a cam sensor with a crank sensor for ignition trigger. All you’re changing by moving the distributor is cam retard offset and rotor alignment.

But if the cam sensor is out of adjustment (distributor indexed wrong), it can cause surging, phantom misfires. On Chevy CSFI systems it will cause the system to bank fire the injectors, which destroys fuel economy in a big way.

Over time, one or both of these sensors could fail, triggering the check engine light. Aside from this symptom, other signs you should keep an eye out for include the following:

- Stuttering or surging engine

- Increased fuel consumption

- Poor acceleration

- Stalling

- Engine misfires

Key Takeaways

While the crankshaft and camshaft are entirely different parts, they need to work together to transfer torque to the transmission and drive wheels.

The main difference between the two parts is that the camshaft opens and closes the valves during the combustion process, while the crankshaft takes the torque from this process and transfers it to the transmission.

Position sensors are essential for both the crankshaft and camshaft. These sensors help the powertrain control module determine the best time to launch intake, compression, combustion, and exhaust activities.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.