Normally, resetting your crankshaft sensor requires the help of a handy tool called a scanner. This is what’s used by professionals to reset your sensor at the auto repair shop. Fortunately, there is a way to reset the crankshaft sensor on your own.

If you’re interested in learning more about crankshaft sensors, what they do, why it’s dangerous to stop one from resetting, and how you can make your crankshaft sensor relearn your vehicle without a scanner, read on.

What Does a Crankshaft Position Sensor Do?

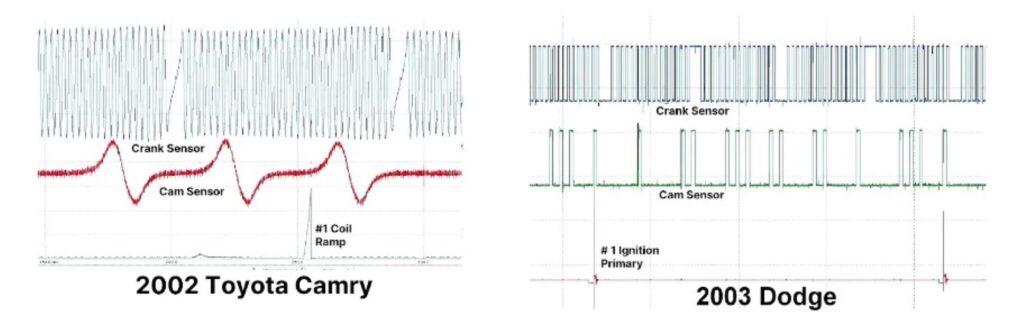

The crankshaft position sensor (CKP) provides the ECM/PCM with input on the precise position of the crankshaft (note the missing tooth in the analog pattern and the spaces in the digital pattern), and measuring the rotation speed of the crankshaft. This information is used for injector pulse timing and ignition timing.

If you listen to an injector with a mechanic’s stethoscope when the engine is idling, and then have someone slightly increase the engine speed, you’ll hear the cadence of the injectors increase along with the speed of the engine. This is because the crankshaft sensor signal frequency increases with engine speed and the injector pulses correlate directly with the input.

Does Disconnecting the Car Battery Reset Your Crankshaft Sensor?

Disconnecting the car battery from your vehicle does not reset your crankshaft position sensor (although this can still depend on the vehicle). Your engine control module will reset all of its code, but this is not the same as resetting and relearning a crankshaft sensor. If your crankshaft sensor is completely broken, then no amount of resetting will fix it. Your best option is to replace it.

Why Is It Important For A Crankshaft Position Sensor to Relearn Your Vehicle?

“Crank learn” information helps the ECM/PCM detect misfires, which is important.

The crank sensor is the basic input the ECM/PCM uses for ignition timing and fuel injection. If there’s no crank sensor input, there’ll be no ignition and no fuel injection. This means the vehicle won’t even start. “Crank relearn” is only necessary on OBD2 vehicles (vehicles newer than 1996 model) with few exceptions.

The crank sensor is the basic input the ECM/PCM uses for ignition timing and fuel injection. If there’s no crank sensor input, there’ll be no ignition and no fuel injection. This means the vehicle won’t even start. “Crank relearn” is only necessary on OBD2 vehicles (vehicles newer than 1996 model) with few exceptions.

–Richard McCuistian, ASE Certified Master Automobile Technician

In terms of clearing the old crankshaft relearn snapshot and enabling the PCM to create a new one, keep in mind that every OEM PCM handles crank relearn a different way. GM even factors in bumpy road surfaces on the fly when using the crank learning comparison.

The ECM/ PCM’s algorithms are programmed to store and update the crank relearn even if it has been cleared because federal OBD2 regulations require misfire monitoring. The engine controller (ECM/PCM) can’t monitor misfires without the baseline snapshot.

For more technical information about crank relearn, read out discussion about cylinder misfires.

How to Test Your Crankshaft Position Sensor

If you spin the engine over and you have fuel injection or ignition spark, you know the crank position sensor is working. However, If you’re checking because of a no-start condition once you find out you have injector operation and spark, it’s best to consider looking for the problem somewhere else.

How to Reset a Crankshaft Position Sensor

Carrying out a crankshaft position reset is a process that’s best done by a professional at an auto repair shop with a scanner.

If you’re curious as to how mechanics can reset your vehicle’s crankshaft sensor with the help of a scanner, here’s what the process may entail:

- The mechanic connects the scanner to your vehicle and turns on the ignition.

- All the necessary information for your vehicle will be inputted into the scanner.

- They will select the Diagnose button, then Control Unit, then Powertrain, and finally select the button that reads ECM or engine control module to run it.

- The Special function will be selected and run.

- The Cam Crank Relearn function will be selected and run.

- After using the scanner, the vehicle’s engine will be restarted.

- The mechanic will optimize your vehicle’s temperature so the crankshaft sensor can reset itself.

For those of you who’d rather learn how to reset a crankshaft position sensor yourself, it is possible to do it without a scanner. You just need to drive around at a steady speed if you want to reset your crankshaft sensor and let it relearn your vehicle.

To get started, follow these simple steps:

- Disable all the accessories in your vehicle and clear all the trouble codes from the code reader.

- Confirm that the coolant and air temperature sensors display the same or similar temperatures (within 5 degrees Celsius of one another).

- Start the engine.

- Park your vehicle or shift it to neutral and remain still for 2 minutes.

- Shift your car to part throttle and accelerate to 55mph.

- Drive around and maintain a speed of 55mph for 10 minutes to let your engine reach its operating temperature.

- Drive around at 55mph for 5 more minutes.

- Decelerate and drive at a speed of 45mph for 25 seconds but do not use the brakes.

- Speed up to 55mph and drive for 15 seconds while maintaining the same speed.

- Repeat steps 8 and 9 three more times.

- Stop your vehicle, but do not leave it in neutral.

- Let your vehicle idle for two minutes to allow your camshaft sensor to relearn.

Bear in mind that resetting a crankshaft position sensor without a scanner takes a lot more time and it’s the furthest thing from convenient.

Replacing Your Vehicle’s Crankshaft Position Sensor

When it’s time to replace a faulty or malfunctioning crankshaft position sensor, it shouldn’t be too difficult to find a high-quality yet affordable replacement with the help of CarParts.com.

The best part? You don’t even have to leave your home to get your hands on a new sensor. Just hop on to our website and use our built-in vehicle selector to narrow down your selection to compatible parts for your ride.

Our sensors are sourced from some of the most trusted manufacturers in the industry. We also have a team of experts that carefully vets products to ensure they meet our standards for quality.

Need parts for urgent repairs? Our warehouses are strategically located all over the US to ensure that customers get their orders in as fast as two business days. Shop and order the parts you need today!

Shop this Project

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.

How to Test Your Crankshaft Position Sensor –

During the testing process, if the engine is turned off and the battery is disconnected, and the Mulitimeter is set to “Volts AC” – with the meter connected to the sensor leads, how does the crankshaft sensor generate a voltage of 0.5 to 1.0 volts?

I understand how the sensor will have internal resistance and will provide a reading in Ohms, while the sensor is disconnected. But where does the voltage come from?

Section: How to Reset a Crankshaft Position Sensor Yourself –

In the list of steps: 5) “Shift your car to “part throttle” and accelerate….. ”

What does “part throttle” mean? Does that mean shift into Drive? I’ve never heard the term “part throttle” before.

Step 12): “Let your vehicle idle for two minutes to allow your “camshaft” sensor to relearn.”

Does the engine computer also relearn the Cam-shaft position, as well, during this procedure? Or should that say, relearn the Crank-shaft position?

Section: How to Reset a Crankshaft Position Sensor Yourself –

This section says: “If you want to learn to do it yourself ….you just need to drive around at a steady speed, if you want to reset your crankshaft sensor.”

Yes, that does sounds easy, “just driving around”. Especially, if someone doesn’t own an expensive scanner.

But then the article states: “… that resetting a crankshaft position sensor without a scanner takes a lot more time and it’s the furthest thing from convenient.”

Time: The procedure, as described, requires (15 min.+ 40 seconds) times 4 sessions. That’s a total of (1 hour, 2 minutes, 40 seconds). Not knowing how it takes to perform the reset using a scanner, driving around probably would take (some amount) more time, but I don’t know if it would be “a lot more time“. Besides, spending an hour driving around, costs almost nothing and (if it really works) saves an expensive repair from a mechanic.

Convenience: The article states that driving around is “the furthest thing from convenient“. To the contrary, being able to fix a serious engine problem, (for free), by just driving around, is actually very convenient! It actually, takes a lot more time to drop the car off at a mechanic for repairs.

My question is: How does the Crankshaft Position Sensor regulate the engine temperature?

What Does a Crankshaft Position Sensor Do? –

Simultaneously, this knowledge helps the module start the engine, regulate the temperature of the engine, and accelerate.

That was stated as one of the functions of a crankshaft sensor, but that wasn’t explained in the article how that happens.

I always thought the temperature was regulated by the mechanical Thermostat in the cooling system? It opens and closes, on its own, as needed, to maintain an optimum temperature. And that is independent of what the crankshaft is doing.

could this manual reset be done with the car on jacks (wheels off the ground) or does the engine have to be under load (car actually moving?)