Your vehicle’s serpentine belt helps transfer power from the engine to various other systems and parts, including the alternator, air conditioning, and steering pump. If your serpentine belt snaps, those systems and components will stop functioning because they stop receiving power. In this article, we’ll be taking a look at the various possible reasons why the serpentine belt on your car failed or snapped.

Accessory Component Issues

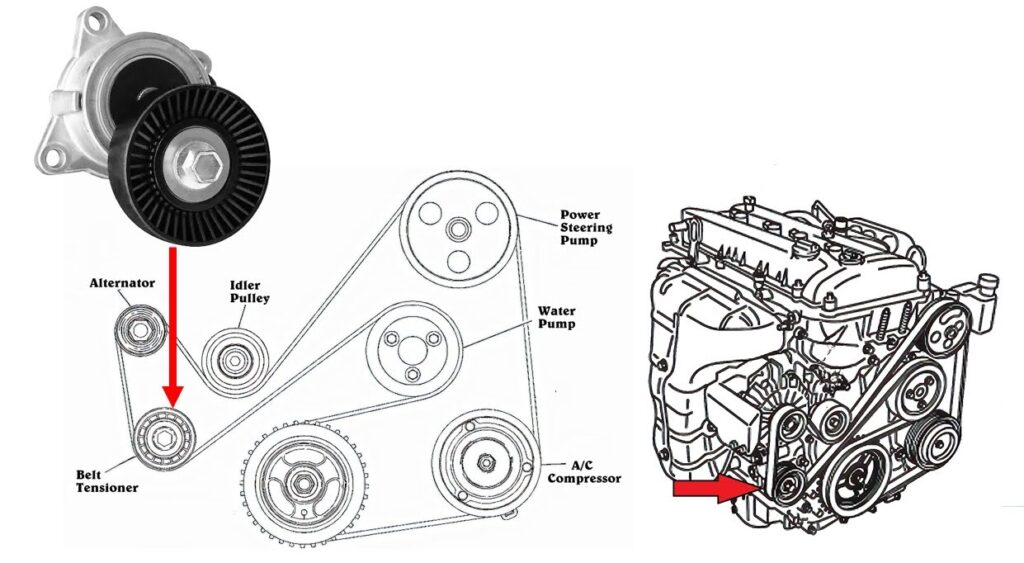

In most vehicles, the serpentine belt runs all the accessory components such as the air conditioning compressor and the crankshaft pulley. If any of the connected components are inoperative or acting up in any way, it can cause issues with the serpentine belt as well, which can cause the belt to develop issues. The most common components causing this would be the A/C compressor or the water pump.

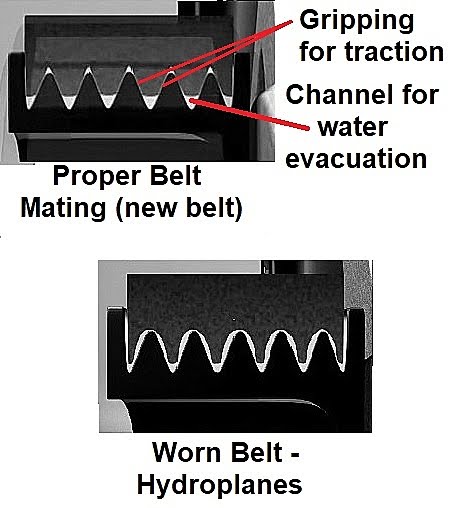

Worn Belt

The serpentine belt will inevitably wear down over time. That’s why you should replace your vehicle’s serpentine belt when necessary. Exactly when you should replace your vehicle’s serpentine belt depends on the belt manufacturer and how you drive. It’s best to replace the belt every 50,000 to 100,000 miles, otherwise it might snap while you drive. Check with your serpentine belt’s manufacturer for the recommended replacement mileage.

Inoperative Pulleys

As we’ve mentioned, the pulleys keep the serpentine belt on the right track as it drives the various components. If any of the pulleys is inoperative, out of line, or damaged, the serpentine belt might slip off its track and squeal or jump off entirely.

Contaminants

If there are any spills under the hood, it can spell disaster for your vehicle’s serpentine belt. Leaking coolant or oil can cause the serpentine belt to squeal and slip.

Misalignment

Damaged pulleys or related accessory components are the most likely causes behind serpentine belt misalignment. That being said, anything that unevenly distributes the load on the serpentine belt can cause it to snap. If one area of the belt is taking on more stress than the others, it’s more likely to snap. You’ll notice uneven wear on the belt if it’s misaligned.

A serpentine belt snapping after around 50,000 miles is in no way uncommon. If it happens while driving, you’ll likely need to stop right away as you’ll have difficulty turning and your vehicle will lose electrical power. Knowing these potential causes behind a snapped serpentine belt can at least help you avoid that situation.

Incorrect Installation

Improper installation can also cause premature serpentine belt wear. Shoddy work will also affect the belt’s performance.

The wrong belt size, incorrect routing along the line, and improper tensioning can all cause the belt to slip. When your vehicle needs a new serpentine belt, hire a trusted mechanic if you aren’t confident you can install the belt properly yourself.

Over-Tensioning

While incorrect tension in general can cause the serpentine belt to wear down prematurely, it’s more likely to snap if it’s over-tensioned. An over-tensioned belt is too tight, which places strain on the system and can cause the belt to warp, stretch, or snap. Over-tensioning also affects the pulleys and connected components. Do a routine check on your vehicle’s serpentine belt to ensure the tension is correct, and loosen the belt as needed.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.