For your vehicle to function properly, all four of its wheels must be aligned when the steering wheel is set straight. If it’s not aligned correctly, your car can develop issues like uneven tire wear and rough handling. So, it’s crucial to make proper wheel alignment a part of your vehicle’s regular maintenance.

What Is Wheel Alignment?

Wheel alignment is the geometric relationship of the wheels to each other, the vehicle, and the road. Ideally, all the wheels should be parallel to each other, perpendicular to their respective axles, and perpendicular to the road. They should also face straight ahead. These conditions ensure minimal rolling resistance and friction as well as optimal traction.

There’s more than one primary wheel alignment angle (caster, camber, and toe), but we’ll focus on caster in this article.

What Is Caster?

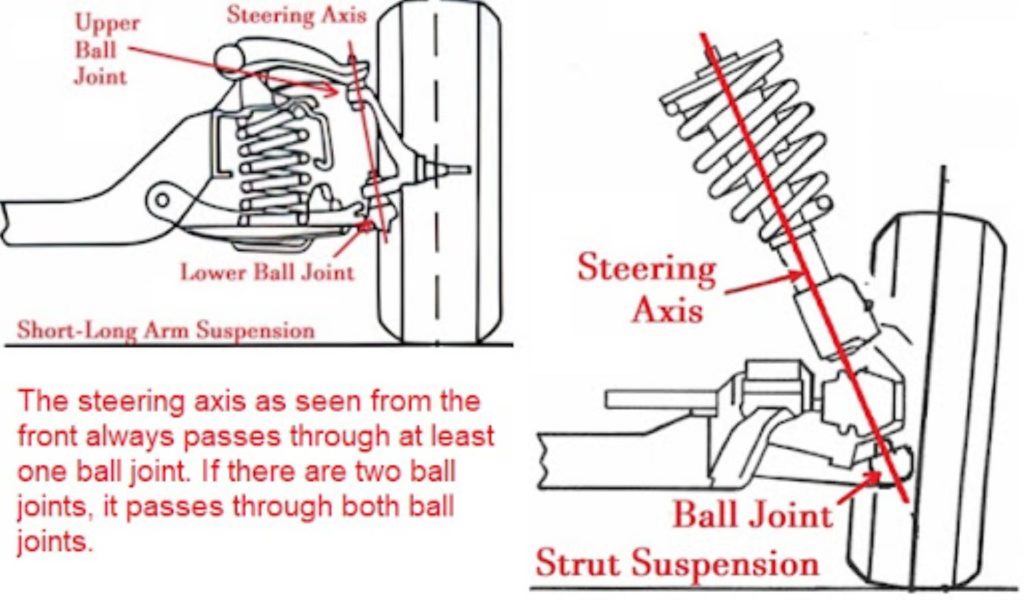

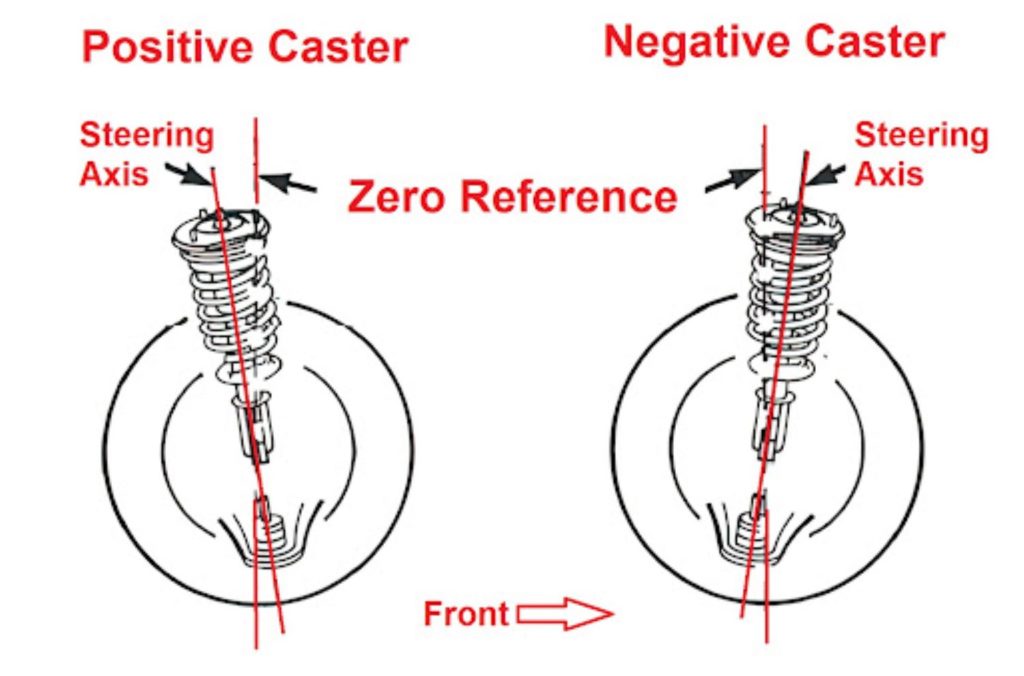

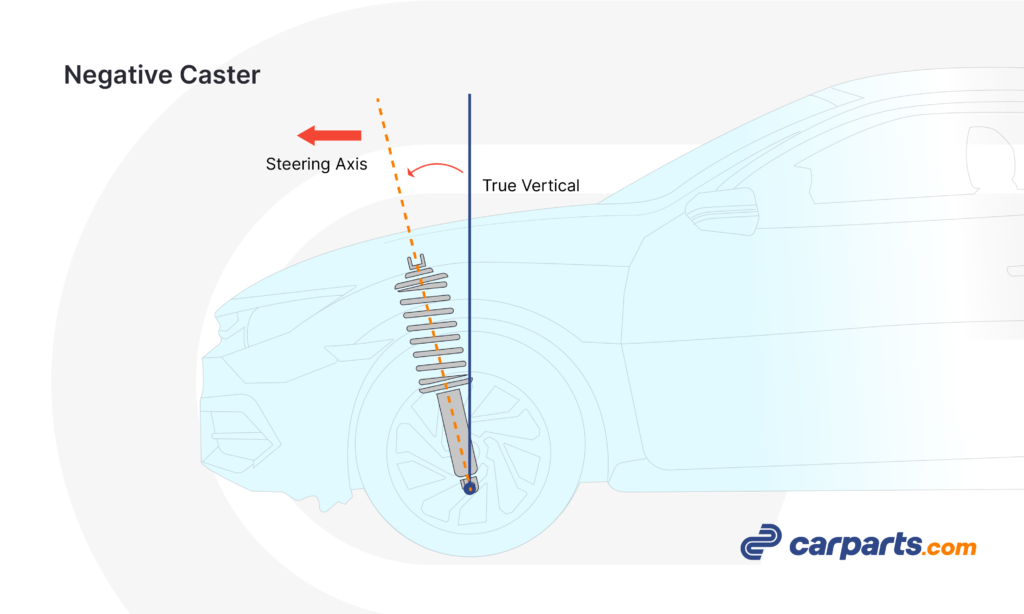

Caster refers to the forward or backward tilt of the steering axis in reference to a vertical line as viewed from the side. It affects steering ability, effort, and return. It is often overlooked because it doesn’t affect tire wear directly. Vehicle caster can either be positive or negative.

How Is Caster Measured?

Caster is measured in degrees. It is gauged based on the vehicle’s front turning wheels because they are the ones involved in steering. Although caster is built into the rear suspension in some cars, it is not measured as part of a four-wheel alignment.

The wheels must be turned 15-20 degrees in each direction to measure caster angles. There are tools that will attach to the hub magnetically for this. They have scales and bubble levels built in to provide caster angle information. Front-end machines use the same method but do so electronically.

The wheels must be turned 15-20 degrees in each direction to measure caster angles.

– Richard McCuistian, ASE Certified Master Automobile Technician

There are two ways to measure the caster angle:

- Use turning plates and a digital or bubble camber/caster gauge

- Using a professional alignment rack and equipment

The video below gives you an idea of how caster is measured with a bubble gauge:

Positive Caster vs. Negative Caster

A positive caster positions the lower ball joint in front of the upper ball joint or strut mount. This results in the tire contact patch hitting the ground in front of the steering system. On the other hand, a negative caster positions the lower pivot point behind the upper pivot point. Here’s how they differ:

Positive Caster

- Positive caster results in stable handling, as it ensures vehicles will go straight with little to no steering wheel correction. It also improves steering wheel returnability after a turn.

- It is common in racing cars because it improves high-speed stability and cornering while increasing steering effort.

- Steering effort increases with positive caster, making road shocks more noticeable when driving over uneven roads.

- Modern vehicles enjoy the benefits of positive caster because they aren’t affected by the heavier steering due to their power steering.

- Positive caster is great for straight-ahead stability due to the wheel’s self-aligning torque.

Negative Caster

- In today’s vehicles, negative caster is rarely specified. It was common in older vehicles that don’t have power steering to help lessen the steering effort.

- Negative caster improves steering but diminishes handling and stability when driving in a straight line.

- A vehicle that pulls to one side when moving in a straight line may have a negative caster.

- If the caster is negative or unequal, the vehicle may be unstable, so it’s more likely to wander. It may need constant steering wheel movement to maintain a straight direction. Note that the caster may increase if the vehicle carries a heavy load in its rear.

Besides the positive and negative caster, vehicles may also have zero caster. It happens when the steering axis is perpendicular to the ground.

What Causes Caster Misalignment?

A huge difference in caster side-to-side can cause a vehicle to drift or lean heavily on one side. Some alignment specs call for a slight difference in caster to compensate for road crown. However, side to side, the caster should typically be within half a degree.

The following issues can also cause caster misalignment:

- Bent spindle

- Bent strut

- Bent control arm

- Mislocated strut tower

- Worn or collapsed control arm bushing

- Weak or broken spring

The caster should be checked and readjusted if needed after these faulty parts have been replaced.

Another factor that could affect caster is ride height. Overloading or spring sag can alter ride height up to several inches, which would affect caster readings by up to a degree or more. This may lead to steering instability or increased steering effort.

If ride height is different from specifications, it should be corrected immediately by making the necessary adjustments. Drivers of vehicles used for towing or hauling heavy loads can invest in accessories, such as variable-rate springs, air springs, overload shocks, and air-assist shocks.

Caster Adjustment

Caster is not adjustable on a lot of vehicles. Most drivers can adjust it by moving the lower or upper pivot point forward or backward using the shims, slots, strut rods, or eccentric cams.

To ensure caster stability, it has to be equal on both sides. If that’s not possible, the right side should have more caster than the left, with a maximum of a half-degree difference, to help compensate for the crown of the road.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.