How to replace the inner and outer tie rods 2009-2014 Ford F-150

To replace the inner and outer tie rods on your F-150 this tutorial was tailor-made for you. You will be asked to lift the vehicle, remove the outer tie rod, remove the inner tied rod and other steps you’ll need to follow in the correct order. You can follow this tutorial of 17 chapters in 90 minutes. Take your ratchet and your 21 mm socket and let’s get started!

Duration

90 minutes

Number of steps

17

Difficulty out of 5

3

Average savings

$120

Parts You Will Need

Tools You Will Need

Step-by-Step Installation

Chapter 1:

Set up

Step 1/1

Turn off your vehicle’s ignition and set the parking brake.

Chapter 2:

Lift the vehicle

Step 1/1

Loosen the stud bolts on the front wheels. Lift the front of your vehicle. Place the vehicle on the axle stands.

Chapter 3:

Take off the wheels

Step 1/1

To be able to replace the inner and outer tie rods on your vehicle, you need to remove the wheels to gain complete access to the steering system. Don’t forget to put the wheels under the vehicle!

Chapter 4:

Tips

Step 1/2

Turn the disc outwards, this will facilitate the following steps. You can now see the outer tie rod.

Chapter 4:

Step 2/2

The components to be removed are very often seized up, so don’t hesitate to brush and to use penetrating oil to make removal easier. With a marker, trace a line between the inner tie rod and the outer tie rod. This will be useful later on during its assembly and disassembly.

Chapter 5:

Loosen the locknut

Step 1/1

With a 24mm wrench, loosen the locknut on the outer tie rod. Hold the inner tie rod with a 15mm wrench to prevent it from turning. The locknut is there to prevent any rotation of the two parts towards each other which could have an impact on the wheel alignment of your vehicle.

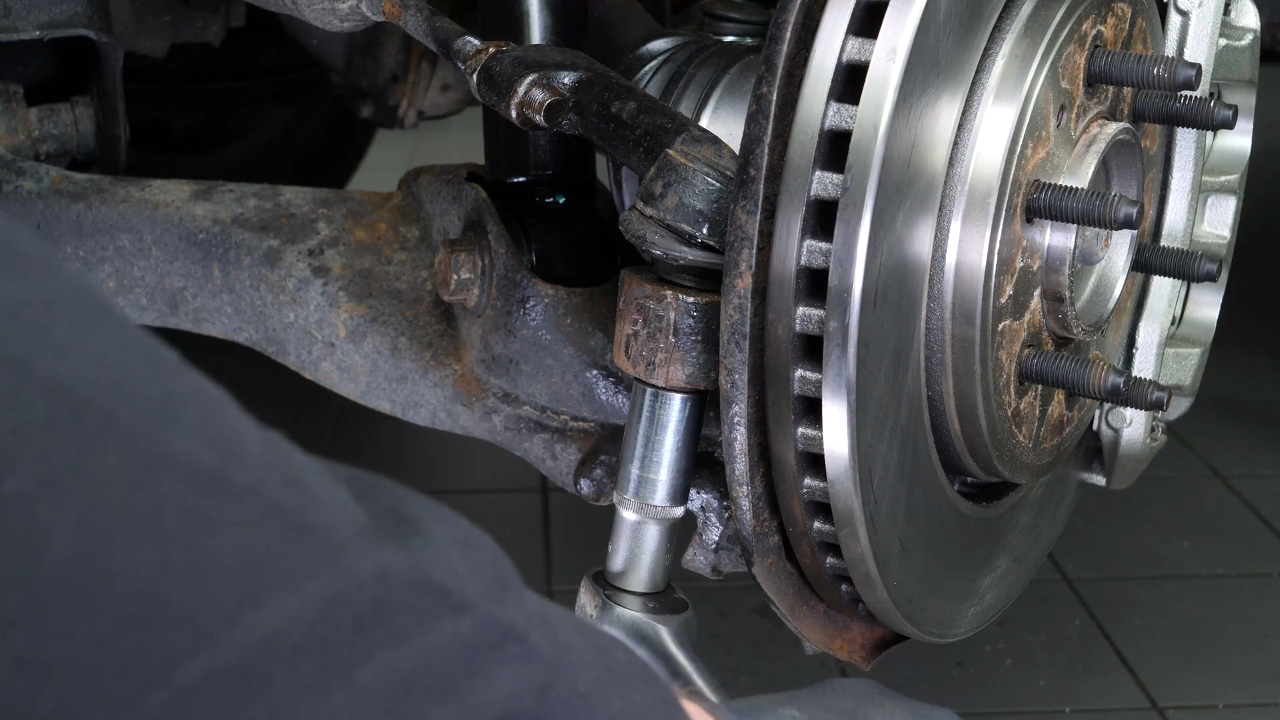

Chapter 6:

Loosen the holding nut

Step 1/1

Using a socket wrench and a 21mm socket, unscrew the outer tie rod holding nut.

Chapter 7:

Remove the outer tie rod

Step 1/1

If you do not have a ball joint puller, a tool specifically designed for this task, take a hammer and hit the knuckle. The ball joint should come out of the knuckle. Unscrew the outer tie rod and remove it.

Chapter 8:

Measure

Step 1/2

Use the markings made with the marker to return the locknut to its original position. Then, measure the distance between the locknut and the end of the inner tie rod using a caliper.

Chapter 8:

Step 2/2

In any case, a wheel alignment check will have to be carried out by a professional soon after having performed this operation. Remove the locknut from the inner tie rod.

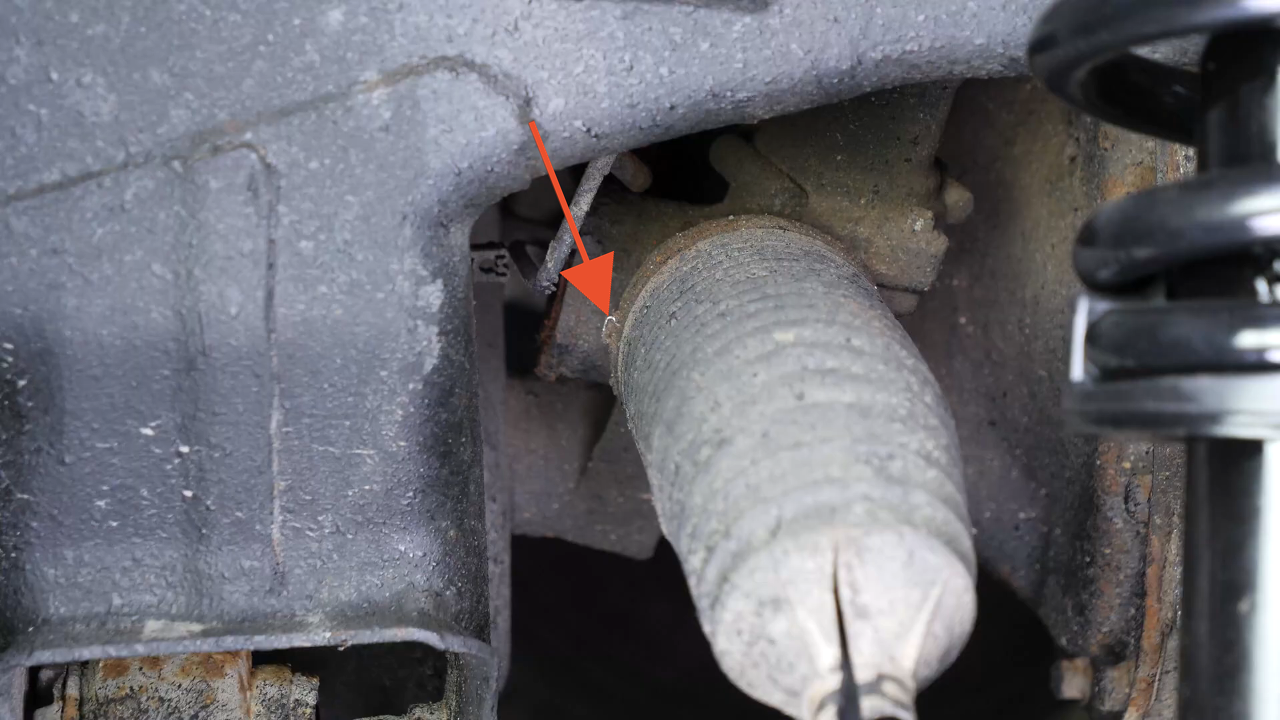

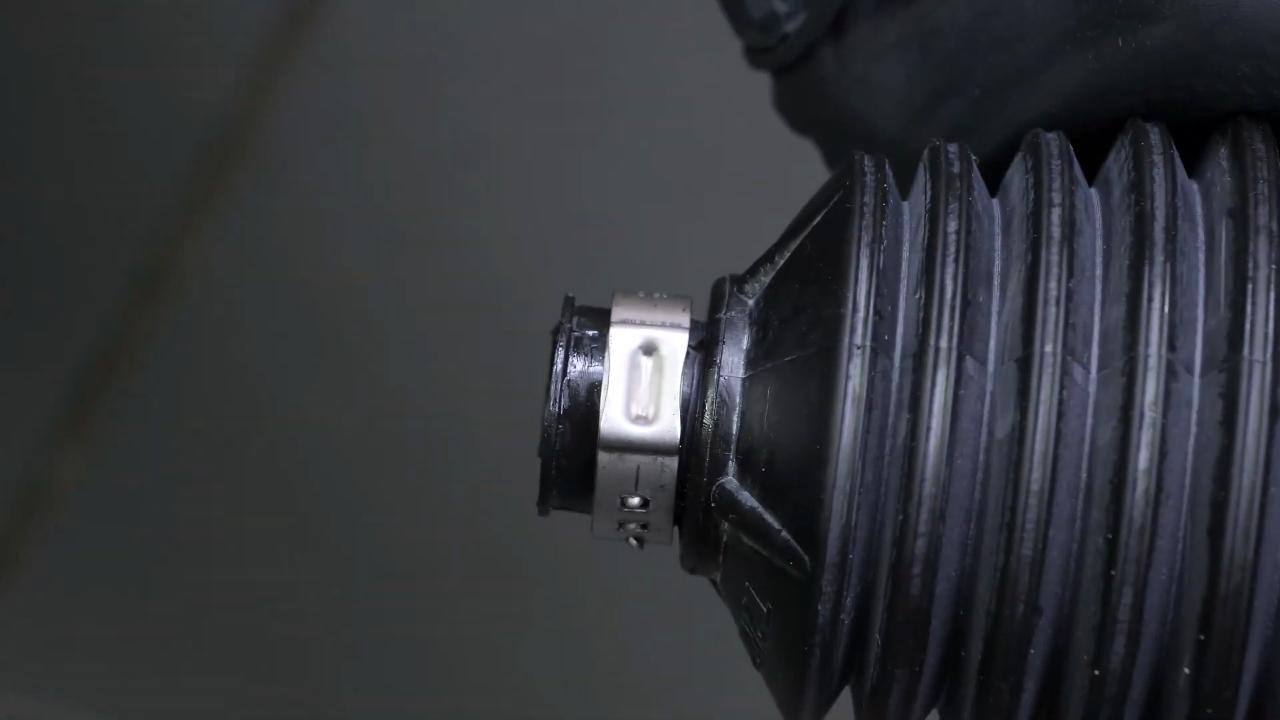

Chapter 9:

Remove the sleeve

Step 1/2

With pliers, remove the external metallic clip on the protective sleeve of the inner tie rod. With a cutter, cut the external part of the sleeve so that you can remove it.

Chapter 9:

Step 2/2

Using a flathead screwdriver, remove the waterproof clip on the sleeve. Remove the sleeve.

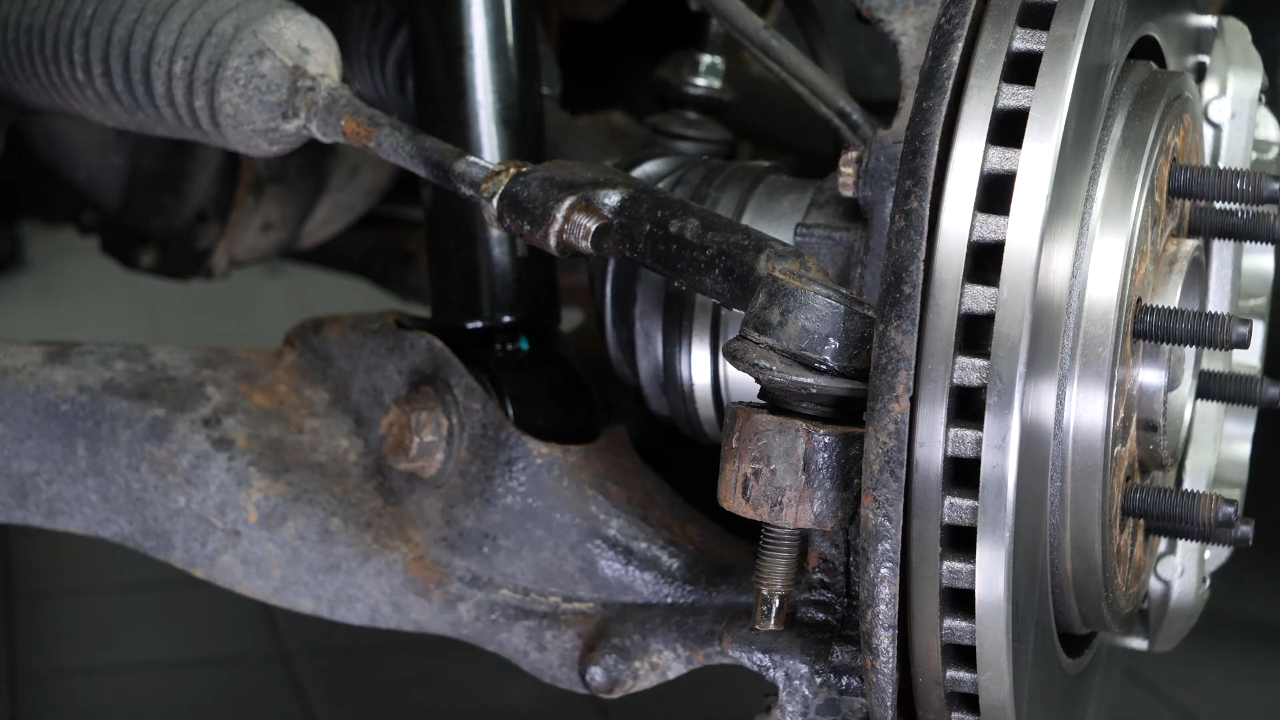

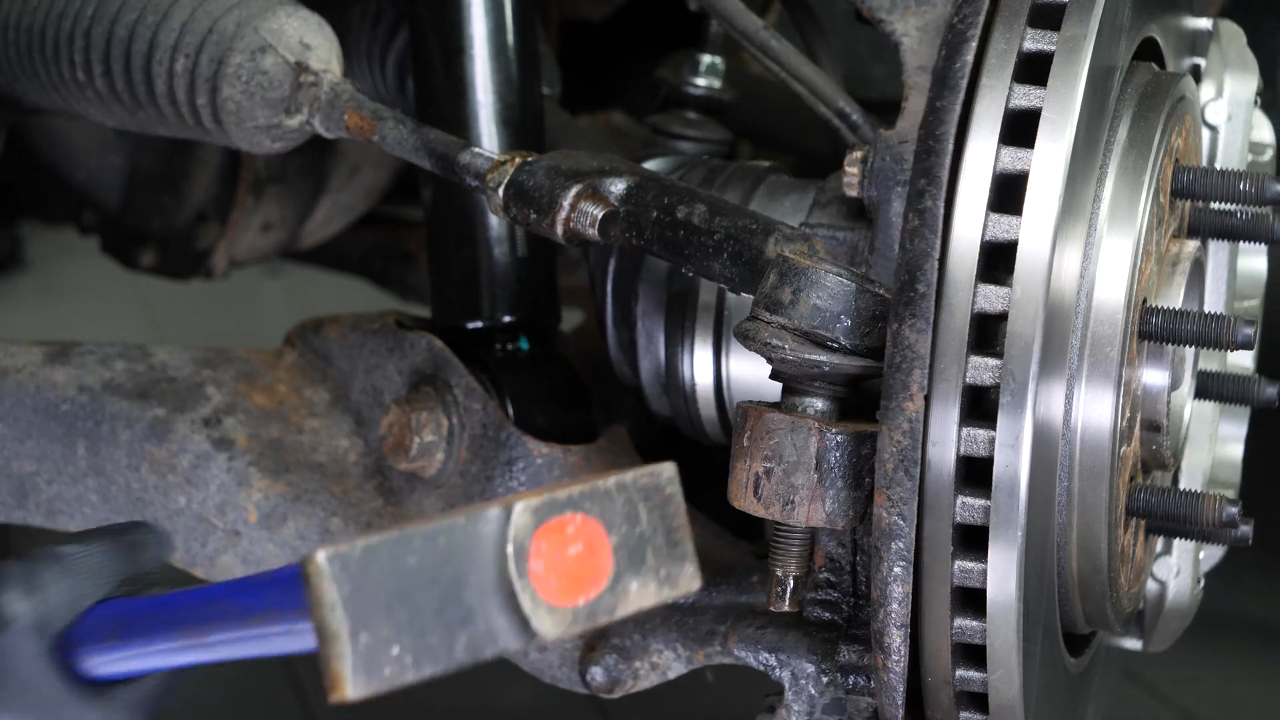

Chapter 10:

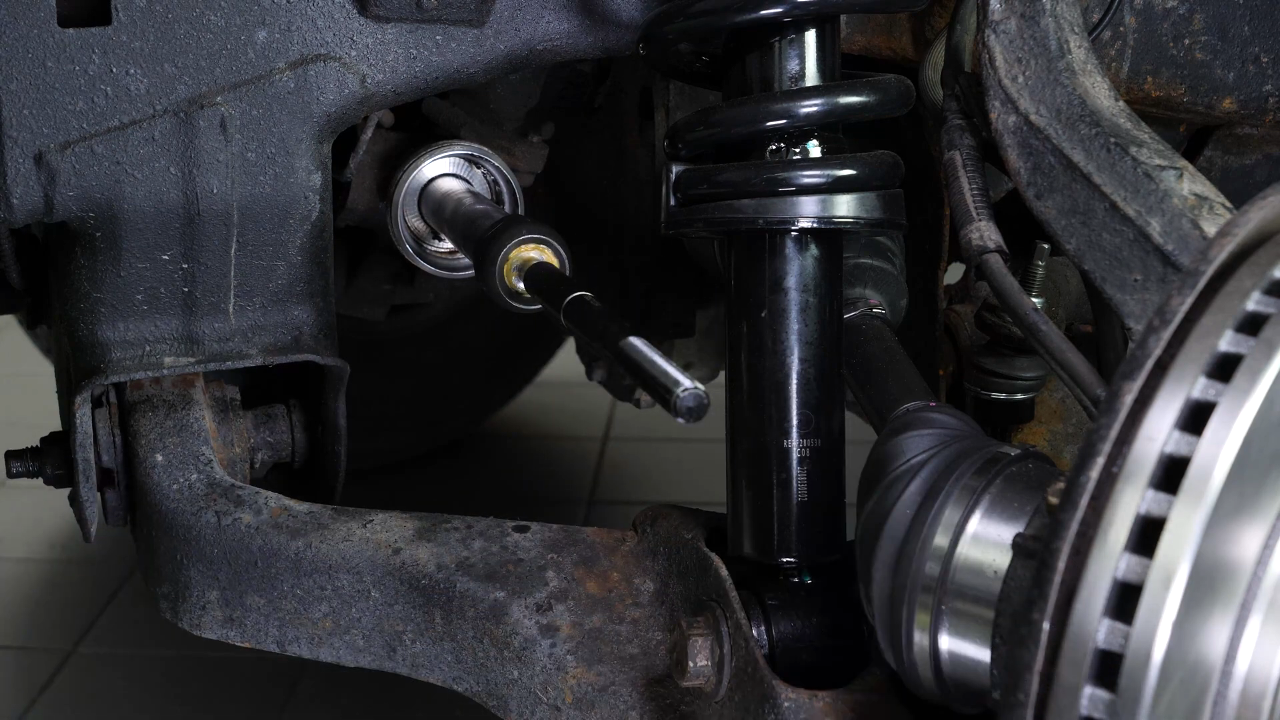

Remove the inner tied rod

Step 1/2

Using a tie rod removal wrench, a specific tool for carrying out this job, you can now loosen everything without difficulty.

Chapter 10:

Step 2/2

To do this, insert the tool up to the fixed part of the inner tie rod, then with the help of a breaker bar, unscrew the inner tie rod. If the inner tie rod is dented, you can loosen it using an adjustable wrench.

Chapter 11:

Prepare the inner tied rod

Step 1/1

Take the new inner tie rod and unscrew the locknut supplied with it. Before installing the new inner tie rod, apply a medium threadlocker to prevent accidental unscrewing.

Chapter 12:

Put the inner tied rod back

Step 1/1

Put the tie rod axle joint back on the steering rack. Still using the same tool or using an adjustable wrench, screw the inner tie rod back in. Finish tightening using a torque wrench. Then remove the tool.

Chapter 13:

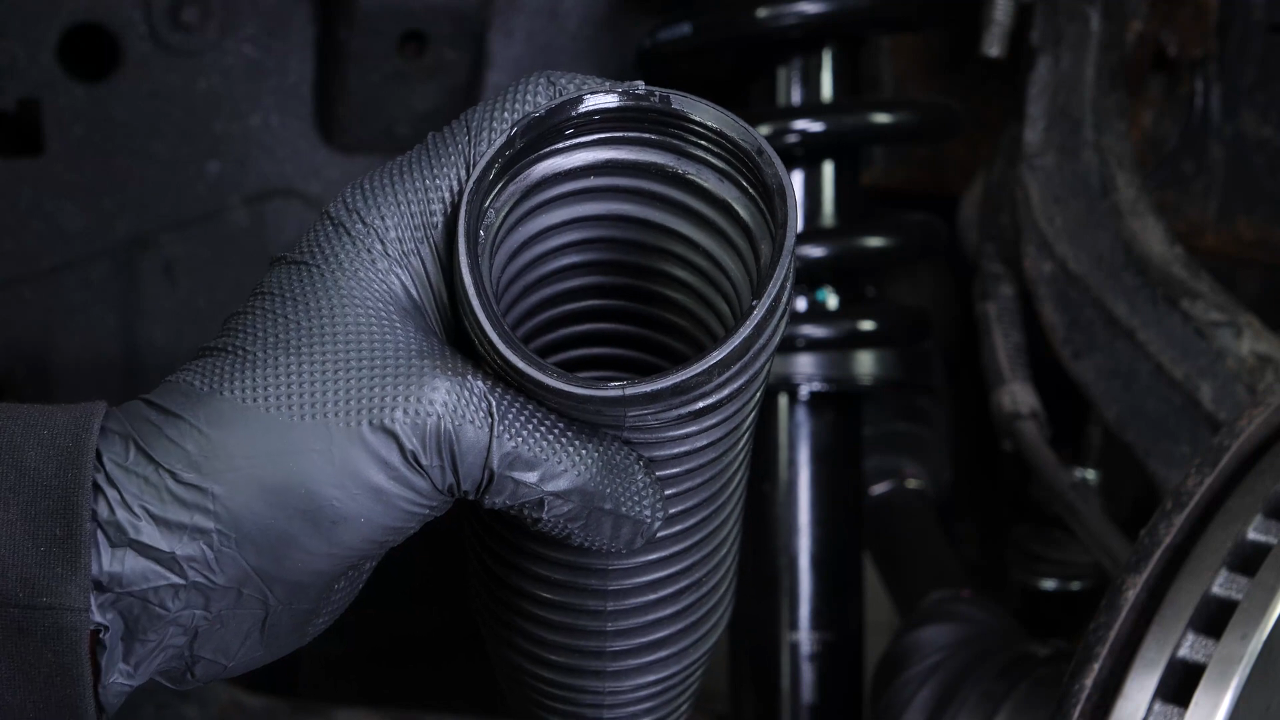

Install the protective sleeve

Step 1/4

Now take the new sleeve, clamps and seal provided in the kit. Install the seal in the sleeve.

Chapter 13:

Step 2/4

Then apply silicone grease to the part of the sleeve that will be in contact with the steering rack, and the part in contact with the inner tie rod.

Chapter 13:

Step 3/4

Put the inner collar on the sleeve, then the outer collar. To make it easier to put the sleeve in place, you can turn the wheels so as to retract the steering rack and thus facilitate the installation of the sleeve.

Chapter 13:

Step 4/4

Put the sleeve onto the inner tie rod. Place the sleeve on the shock stearing rack. Then position the inner collar correctly. You can now crimp the collars with collar pliers, or pincers.

Chapter 14:

Install the locknut

Step 1/1

Screw the locknut back on until the distance measured with the caliper is reached.

Chapter 15:

Put the outer tie rod back

Step 1/4

Take the new outer tie rod and unscrew the locknut supplied with it. Put the outer tie rod back in place until it touches the locknut.

Chapter 15:

Step 2/4

During this operation, you will work on the steering system of your vehicle. A professional alignment check should be performed to ensure that your steering system is once again perfectly adjusted and functioning.

Chapter 15:

Step 3/4

Using a wire brush, scrub the knuckle, then apply silicone grease to the flat part that will be in contact with the sleeve of the outer tie rod. Do not grease the inside of the cone.

Chapter 15:

Step 4/4

Put the outer tie rod back in place in the knuckle. Put the nut supplied with the new part in place and tighten it using 21mm wrench, and a 10mm wrench to lock the rotation of the threaded rod. Finish tightening using a torque wrench.

Chapter 16:

Finalise the tightening of the locknut

Step 1/1

Finish tightening the locknut using a 24mm wrench by holding the inner tie rod still with the help of a 17 mm spanner to avoid damaging the tie rod.

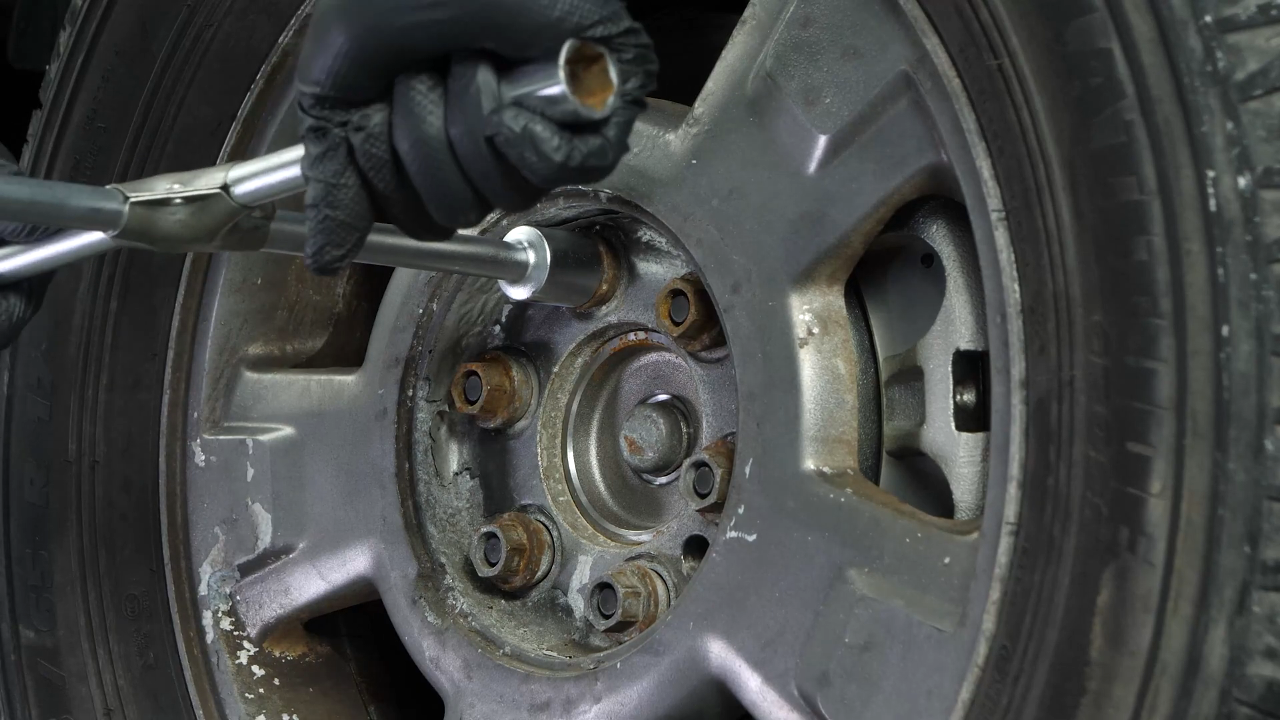

Chapter 17:

Finalise the reassembly

Step 1/2

Then, you will be able to put the wheels back on your vehicle. Put the car back on the ground and block the wheels properly.

Chapter 17:

Step 2/2

Operation completed!