Spark plugs are responsible for creating the spark that will ignite the air-fuel mixture to kickstart the combustion process. Without them, you can’t expect to get anywhere with your vehicle other than your garage.

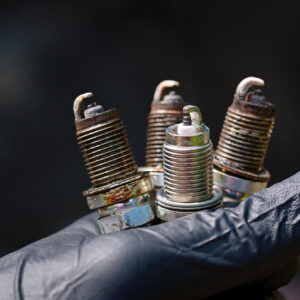

Several issues can arise with one or more spark plugs. One of these is a buildup of black deposits.

What Causes New Spark Plugs to Turn Black?

When a new spark plug turns black, that doesn’t necessarily mean that you received a faulty unit. This phenomenon is called carbon fouling, which can be caused by four things:

- Excessive idling

- Defective thermostat

- Overly rich air-fuel mixture due to a fuel system fault and;

- Weak ignition system output

Excessive Idling

Whenever a vehicle excessively idles, the engine isn’t working at its optimal operating temperature. This also means fuel doesn’t combust completely, which can be hard for the engine.

The fuel residue that stays during incomplete air-fuel combustion can eventually contaminate the engine oil and cause the spark plugs to turn black.

Defective Thermostat

A defective thermostat won’t necessarily cause your spark plugs to turn black.

However, it will be hard for you to determine whether or not the engine is operating under the right temperatures, which can then affect the condition of your spark plugs.

Overly Rich Air-Fuel Mixture

An overly rich fuel condition means there isn’t enough oxygen to match the amount of fuel.

Too much fuel can cause carbon to build up, which will eventually ground the spark and cause the spark plug to stop firing.

In most cases, an overly rich air-fuel mixture indicates a problem with several fuel system components, including the following:

Oxygen Sensor

The oxygen (O2) sensor measures the oxygen content of the exhaust.

Typically installed in the exhaust manifold or situated downstream from the manifold in the exhaust pipe, the sensor sits directly in the path of the exhaust gas stream to monitor O2 levels.

If the powertrain control module (PCM) is unable to get accurate readings from the O2 sensor, the computer won’t be able to adjust fuel levels accordingly, which can result in an overly rich mixture.

Mass Airflow Sensor

A mass airflow sensor helps the PCM determine the amount of fuel needed and base pulse-width numbers.

The sensor also backs up the throttle position sensor in case it fails.

If a problem with the mass airflow sensor has been detected, the engine computer will use the readings from the throttle position sensor and engine speed to calculate fuel delivery.

Over time, dirt, oil, silicon, and other contaminants can coat the sensing wire, which can overestimate the amount of air entering the engine at idle and cause the fuel system to go rich.

Under higher engine speeds, the contamination can cause the sensor to underestimate the amount of air entering the engine, resulting in a lean fuel mixture.

Manifold Pressure Sensor

The PCM relies on the manifold pressure sensor to get the following information:

- Engine load

- Altitude, fuel, and spark control calculations

- EGR system operation

- Vacuum increases

- Load detection

Similar to other sensors, a problem with the manifold pressure sensor can result in inaccurate fuel delivery calculations. In the case of the manifold pressure sensor, it might report the wrong air pressure numbers to the computer, resulting in a rich fuel mixture.

Coolant Temperature Sensor

The engine coolant temperature sensor monitors the coolant temperature so that the PCM can make the necessary adjustments in the fuel mixture.

Typically, a cold engine will require a rich fuel mixture to prevent stalling. Meanwhile, a warm engine will require a leaner fuel mixture to provide maximum fuel economy while minimizing exhaust emissions.

The PCM needs to determine the engine temperature to properly control the spark timing and fuel mixture.

Problems with the coolant temperature sensor can result in an overly rich or lean fuel mixture.

Fuel Pressure Regulator

The fuel pressure regulator works with the fuel pump to maintain the appropriate amount of pressure drop at the injector tips.

Depending on certain issues, the fuel pressure regulator can leak and affect the amount of fuel delivery.

Weak Ignition System Output

A weak ignition system output can be attributed to the following parts:

Spark Plug

Spark plugs are often the root cause of engine performance problems. The spark plug is prone to developing soot, which can be caused by other parts from various systems.

Spark plugs can also have wet, oily deposits with little electrode wear, which is commonly referred to as oil fouling.

Spark plugs covered in oil are an indication of oil entering the combustion chamber. In most cases, this issue can be traced to the following:

- Worn or broken piston rings

- Worn valve guides

- Defective or missing valve stem seals

Ignition Wire

In some cases, a weak ignition wire will still run fine under cold temperatures. When temperatures rise, however, the wire insulation can break down and cause the engine to misfire.

A compromised insulation material will usually have its molecules farther apart, creating a new path for electricity to flow instead of jumping the gap of the spark plug.

Ignition Coil

An ignition coil has a negative and positive terminal. The negative terminal is attached to the ignition control module, which opens and closes the primary ignition circuit.

Once the ignition switch is turned on, voltage should be available at both terminals if the coil’s primary windings have continuity.

It’s possible for the ignition coil to malfunction over time due to the constant charging and discharging cycles. If the ignition coil is weak, the engine will idle as usual, but it can break up under load.

Key Takeaways and Solutions

A black spark plug is usually an indicator of fuel and ignition system problems. Also known as carbon fouling, this issue can affect even newly installed spark plugs.

Excessive idling and a defective thermostat are also potential reasons why the spark plug can turn black.

When resolving this problem, a thorough inspection of the engine is important to accurately determine the part that’s causing the problem. Common solutions typically involve replacing the faulty parts or cleaning them to keep them functional.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.