Classic cars have mechanical brakes that use physical cables to engage and disengage the brakes. While you can boost mechanical braking performance with upgrades, replacing old-fashioned brakes with modern hydraulic brakes is a better option.

Note, however, that by the mid-1930s, most American car manufacturers had transitioned to hydraulic brakes. But if you’re restoring and refitting a vehicle older than that, this article might help.

Mechanical-to-hydraulic brake conversion works best when you use a hydraulic brake conversion kit, but you can do the project yourself.

What Is Hydraulic Brake Conversion?

Hydraulic brake conversion is the process of replacing mechanical brakes with hydraulic brakes. Installing hydraulic brakes upgrades the braking performance of the classic car to modern standards. If you have the right tools and sufficient experience in DIY car maintenance, you can do the conversion job yourself.

What Do You Need For Hydraulic Brake Conversion?

At a minimum, hydraulic brake conversion requires a hydraulic brake conversion kit. This contains the parts and components necessary for replacing mechanical brakes with their hydraulic equivalents.

There are two main types of hydraulic brake conversion kits according to the level of modification required to install the new brakes in your vehicle. Each type has advantages and disadvantages.

No-Modification Hydraulic Brake Conversion Kit

This hydraulic brake conversion kit uses the gaps in your vehicle’s frame to attach and arrange new parts. Many kits also retain the existing handbrake handle that controls the rear brake cable.

With a no-modification kit, you don’t need to cut, drill, or weld parts of your classic car. You only need to figure out where the new parts must pass through.

The biggest drawback to no-modification hydraulic brake conversion kits is cost. A kit can set you back by hundreds or thousands of dollars. Not everyone can afford the price tag of a no-modification kit.

Still, if you prize the appearance of your classic car and want to bring its braking performance up to today’s standards, don’t skimp on one of your major long-term investments. Go for a no-modification hydraulic brake conversion kit.

Hydraulic Brake Conversion Kit

Other hydraulic brake conversion kits require you to alter your vehicle. Depending on the body panels and the brake parts that need to pass through them, you might have to cut and drill openings in various body panels. Furthermore, you might have to use a welder to join parts and seal openings.

Are you unsure about modifying your classic car using a hydraulic brake conversion kit? Bring your vehicle to a trusted auto repair shop and get professionals to do the job.

Other Tools

A no-modification kit needs fewer tools to install its parts in your classic car. However, if you chose a hydraulic brake conversion kit that requires modification, you might need heavy-duty power tools like power drills, saws, and welders.

What’s in a Hydraulic Brake Conversion Kit?

Hydraulic brake conversion kits usually include the following parts:

- Four-hole coupling plate

- Hydraulic brake assemblies

- Hydraulic brake flange kit

- Hydraulic brake fitting kit

- Hydraulic hub drums

- Hydraulic override coupling

- Motor coil

- Bundy tube

Note that you might not need to buy a full hydraulic brake conversion kit. Some conversion jobs only need certain parts and components.

Finding the Right Hydraulic Brake Conversion Kit

Manufacturers designed hydraulic brake conversion kits for exclusive use with a specific make and model. You usually can’t install the new brake parts and components in an incompatible vehicle. Thus, choosing a compatible brake conversion kit is crucial if you want to upgrade the brakes of your classic car.

Mechanical Brakes vs. Hydraulic Brakes

Given the stringent requirements, you might ask yourself if a hydraulic brake conversion is worth the expense and trouble. It is, and you’ll understand why if you think about how your vehicle’s braking system works.

The braking system stops your vehicle by generating friction that slows down the wheels. They press a component against a spinning surface connected to the wheel. In drum brake systems, the brake shoes are the components that come into contact with the brake drum. Meanwhile, disc brake systems push brake calipers against the brake disc.

How Do Mechanical Brakes Work?

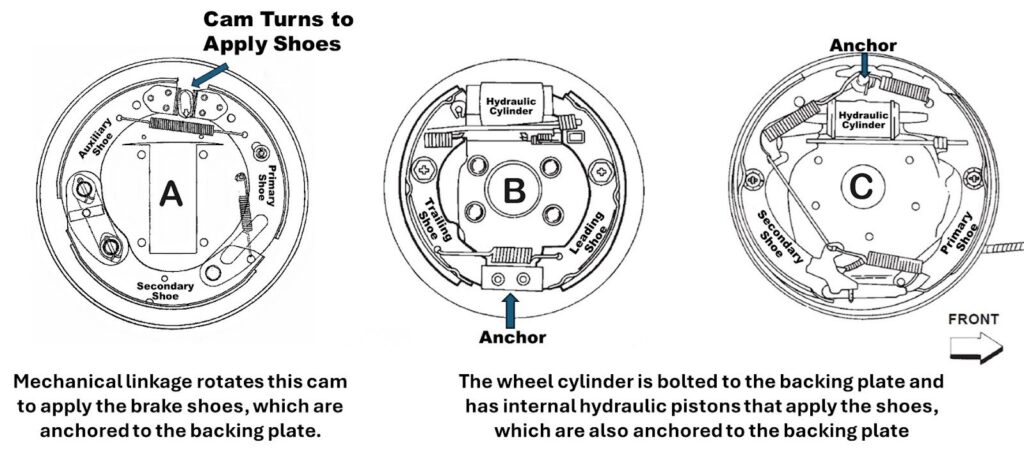

Mechanical brakes get their name from the linkages connecting the brakes with the brake pedal or lever. The mechanical linkages were often cables wrapped around the wheel. If you pressed the brake pedal, the cables pulled the brake shoes into the drum brakes.

Early vehicles used mechanical brakes as their primary means of stopping their movement. In modern cars, the parking brake is usually mechanical and is separate from the main brake.

Mechanical brakes offered a couple of advantages over later types of brakes. They’re less expensive because they use drum brakes.

How Do Hydraulic Brakes Work?

Hydraulic brakes use hydraulics, a mechanical function that leverages the force of liquid pressure. Instead of using mechanical parts to transmit force and move brake parts, hydraulic systems use liquid pumped through hydraulic cylinders that move pistons.

In a hydraulic brake system, the master brake cylinder contains hydraulic fluid that can transmit and amplify force. When you press the brake pedal, you apply force to a piston in the master cylinder. The hydraulic fluid in the cylinder transmits the force through the brake system until it reaches the pistons connected to the brake pads. The pistons press the pads against the surface, generating friction to slow the wheels and the vehicle.

Compared to mechanical brakes, hydraulic brakes can generate more braking power. They can also consistently deliver the required braking force at each wheel. Furthermore, they can work with modern features like advanced anti-lock brakes (ABS), stability control, power-assisted brakes, and brake assist. They also take up less room than mechanical brakes, especially the hydraulic brakes that use disc brakes instead of bulky drum brakes.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.