The last thing you need on a summer road trip is your car suddenly stalling in the middle of the highway with the baking-hot sun scorching everything in its path. The “Check Engine” light should turn on when this happens but it’s going to be too late to fix anything under the hood at this point. If it’s the crankshaft position sensor that has problems, these should have been addressed way before you started planning your summer vacation.

In this article, we’ll tell you everything you need to know about the crankshaft position sensor, including symptoms to look out for and how to replace this component if you want to take a stab at DIY repair.

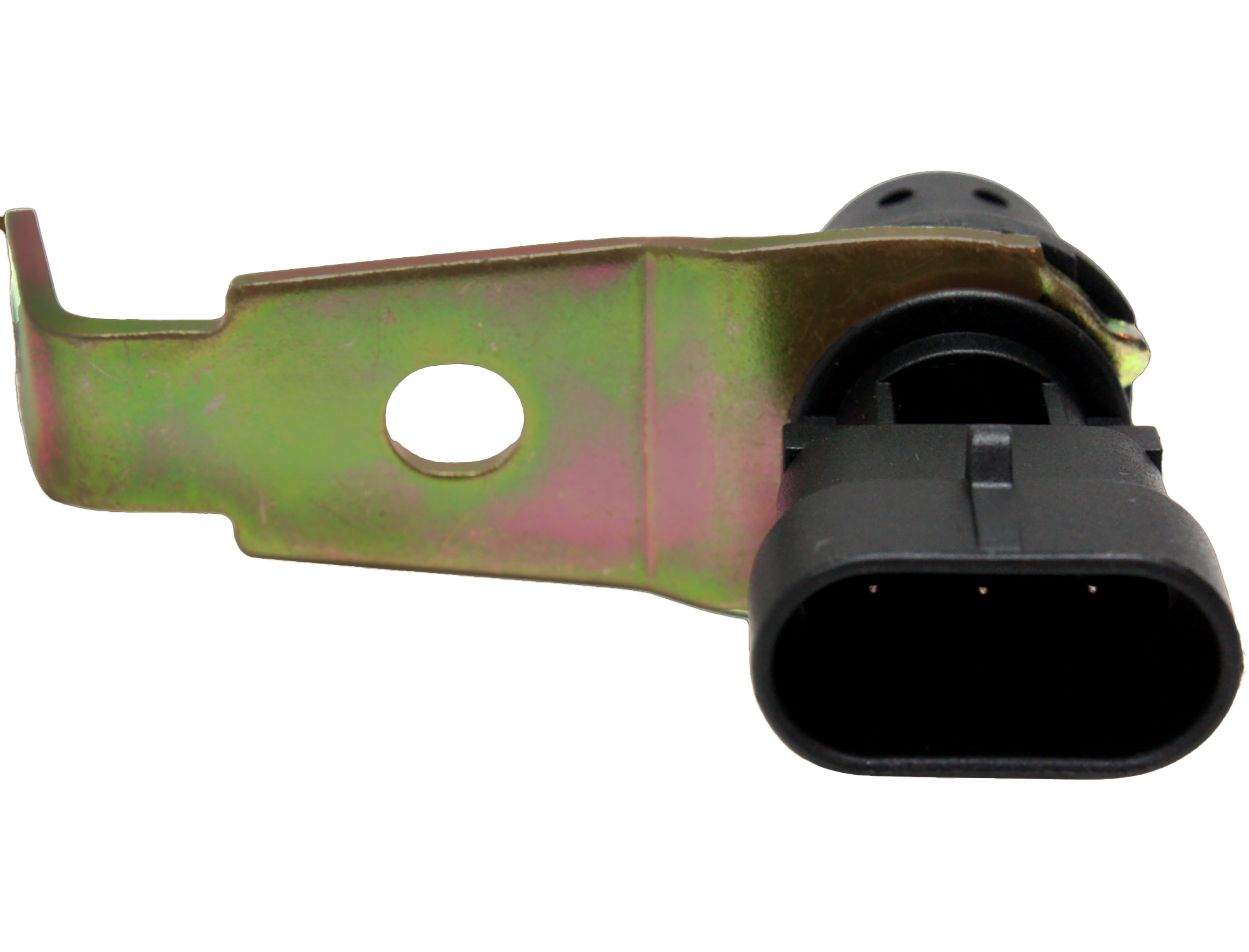

The Crankshaft Position Sensor

So what is a crankshaft position sensor and what does it do?

The crankshaft position sensor (CKP) is a device in most modern automobiles that registers the rotational speed and position of the crankshaft, and sends that data to the engine control unit (ECU), so it can regulate engine processes like ignition and fuel injection according to operating conditions.

Basically, what this means is that the engine will not perform efficiently or will not work at all if the crankshaft sensor is faulty. The following are signs of a bad crankshaft sensor to look out for:

- Engine won’t start – Starting issues are the most common signs of a bad CKP. These can happen intermittently or, in some cases, the engine could fail to start altogether.

- Stalling – Any significant damage to the sensor or its wiring could result in a host of engine problems. If the sensor’s signals get cut off while the engine is running, the car could stall on the road.

- Check engine light turns on – Modern vehicles have safeguards to keep the engine working as efficiently as possible. When something goes wrong with the crankshaft position sensor, the computer should detect the problem and the check engine light will illuminate. Take note, however, that this could indicate a variety of problems related to the engine, so it’s advisable to get a trouble code reading to diagnose the issue properly.

- Rough idling and bad gas mileage – Prepare for a bumpy ride when your CKP starts to go bad. A faulty sensor will have difficulty tracking the crankshaft’s position, resulting in unnatural vibrations when idling. Worse, the shaking and grinding combined with the ill timing of fuel injection in the engine will more than likely cause bad gas mileage.

What Causes a Crankshaft Position Sensor to Go Bad?

- Excess heat – It’s always hot in your engine but if the temperatures surpass normal levels, the plastic casing protecting the crankshaft sensor can melt and damage the component.

- Wiring harness problems – Ground or return circuit issues could result from loose wiring, which, in turn, could cause voltage disruption and damage the crankshaft position sensor over time.

- Faulty wheel and pin – The crankshaft sensor operates by measuring the magnetic pulses generated by a series of pins or a toothed wheel. Damage to any of these could disrupt pulse pattern, resulting in inaccurate information about the crankshaft’s speed. The CKP could fail if this issue is left unaddressed.

DIY Guide to Replacing the Crankshaft Position Sensor

It’s always best to leave complex repair jobs to a professional mechanic but if you want to take a stab at replacing the crankshaft sensor yourself, here’s a step-by-step guide you can follow:

Step 1: Before anything else, make sure to disconnect your car battery to avoid damaging your car’s electronic panel.

Step 2: Refer to your owner’s manual to find the crankshaft position sensor’s location. The position varies depending on a vehicle’s year, make, and model, so refer to your manual to locate it quickly.

Step 3: To remove the crankshaft sensor, disconnect the wire harness. Take note of the wiring’s position (you can probably take a picture using your phone) because you’ll need to reattach it in the exact, same order when you install the new sensor.

Next, remove the bolt using a socket wrench, then proceed to replace the faulty sensor with the new one. This process should be as simple as placing the replacement sensor in the same slot. Note that you’ll also need a new O-ring because you can’t use the old one anymore.

Step 4: As mentioned, reattach the wiring harness in the exact, same order. The unit should lock into place, but if doesn’t, you can manually adjust it using a paper spacer.

Step 5: Finally, reconnect your battery.

Engine problems should be diagnosed immediately the first time you notice symptoms. Don’t delay because even simple issues could end up being critical ones that could cost you a lot of money and a ton of headache if they are left unaddressed.

Getting a New Crankshaft Position Sensor

A faulty crankshaft position sensor is bad news. If it fails, your vehicle won’t know how to set the ignition timing, and your engine will probably refuse to start. It can also negatively affect your engine’s performance and cause acceleration issues. Unless you want to deal with all these engine issues, you should replace your crankshaft position sensor as soon as possible. Luckily, getting a new crankshaft position sensor is fast and easy with CarParts.com.

CarParts.com offers a wide selection of high-quality crankshaft position sensors, sourced from only the most trusted manufacturers in the industry. Don’t forget to use our vehicle selector, so you can easily browse through all the on-hand parts that are compatible with your ride. If you need any help, don’t be afraid to reach out to our customer service team. We are always available, so you can shop without worry 24/7.

Don’t wait until your faulty crankshaft position sensor causes engine problems. Check out our catalog of high-quality crankshaft position sensors at CarParts.com and order one today!

Shop this Project

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.