Control arms are basically just big hunks of metal. Unless they suffer impact damage from, say, a collision, they rarely fail. Instead, what usually require replacement are the bushings and ball joints that are built into the control arm.

On some cars, the bushings and joints are non-serviceable, meaning the entire control arm must be replaced when these items go bad. Other times, it’s just more efficient to replace the entire control arm instead of the individual joints and bushings, which are often press-fit and difficult to remove.

Front Control Arm Inspection Methods

There are a variety of ways you can check the control arms, control arm bushings, and ball joints for wear. Obviously, you’ll need to raise and support the vehicle safely to perform most of these inspections. And don’t forget to put on your safety glasses.

Note: The following are general guidelines for educational and entertainment purposes only. Consult your vehicle’s factory information for specific repair instructions and recommended safety procedures.

Perform a Visual Inspection

The first step is to perform a visual inspection. Check the control arm itself for issues, such as cracks, distortion, and major rust damage. You’ll also want to inspect the control arm bushings for tears and major cracks (minor weather checking is normal). Finally, check the ball joints for torn grease boots and other damage.

Check the Control Arm Bushings for Play

Checking the control arm bushings is pretty easy. Place a pry bar on the control arm near the bushing. Then attempt to move the control arm back and forth (you may also want to try moving it downward, depending on the bushing design). Don’t use a lot of force while doing this—be gentle.

A slight amount of movement from a control arm with rubber bushings is normal. If, however, there’s a significant amount of movement from the control arm, that’s a good indication the bushing is worn and needs to be replaced. As a general rule of thumb, some experts say 1/8” of movement or more indicates a rubber control arm bushing is worn and should be replaced

Also, in some instances, you may be able to spot bad control arm bushings with the vehicle on the ground. Have a friend turn the steering wheel back and forth while you watch the control arm. If the bushings are worn enough, you may be able to see the arm and/or bushings moving back and forth excessively.

Check the Ball Joints for Play

Next, you’ll want to check the ball joints for play. The formal method for this inspection varies a great deal, depending on the type of suspension your car has. Generally, the procedure involves checking the joint for radial (horizontal) and axial (vertical) play by pushing and prying on the wheel/tire assembly. However, some automakers suggest you pull on the control arm itself. Consult your vehicle’s factory repair information to determine what type of suspension your car has and how to properly check the ball joints.

There are a couple of other less formal methods you can use to check for ball joint play as well. The first technique requires the vehicle to be parked with all four wheels on the ground. Have a friend turn the steering wheel back and forth while you watch the ball joint. In some cases, you’ll be able to see excess radial play if the joint is worn enough.

Another method I often use, which is, admittedly, somewhat unorthodox, requires a large set of slip-joint pliers. Carefully place the ball joint vertically between the jaws of the pliers and squeeze. You will see visible axial movement if the joint is worn.

Finally, some ball joints have built-in wear indicators. Measuring wear with this design is simple. With the vehicle on the ground, peek under the car. Check whether the wear indicator (the raised area around the grease fitting) is receded into the joint. If it is, the joint is worn and should be replaced.

Get Reliable Control Arms Shipped to Your Home

Control arms are tough parts, but even they can wear out and fail if you push them hard enough. If you have a bad control arm on your hands, it’s best to stop driving your car until you’ve replaced the faulty part. Fortunately, CarParts.com makes it easy to find a suitable control arm, and we deliver your order straight to your doorstep.

CarParts.com offers a wide selection of high-grade replacement parts and accessories, such as control arms. We operate several distribution centers in strategic locations, and the facility nearest you will process your order to save time. Furthermore, we streamline the search process for the control arm that fits your requirements and budget. Simply enter your car’s details into our website’s vehicle selector, and you’ll find the most suitable products in our extensive catalog. If you have questions about our products, such as their price and fit, our customer service team is available 24/7.

So, what are you waiting for? Make CarParts.com your one-stop shop for dependable control arms, and enjoy great savings today.

Products Mentioned in this Guide

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.

Ball Joint

Ball Joint

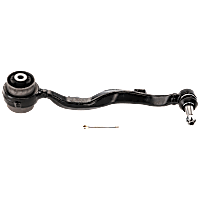

Control Arm

Control Arm

Control Arm Bushing

Control Arm Bushing

My 99pathfinder I had a struggle kinda hard to shift 4wd.

2#.when driving and drive over s rock the one front wheel started to shake like almost tire was loose that had to slow down to stop

3#car would not move reverse, ten minutes I checked the transmission fluid it was low. The transmission trays the screw’s we’re lose about half turn. Once that was taken care off I refuel the oil on the bottom axle and trans fluid

4#now it drives with out a problem just a little noise coming from the transfer, ,.?? Now my 4wd shift without a problem just like if it wasn’t connected.

So I checked the bottom All the transmission fluid was outside mix with motor oil outside dripping still trying to get home I heard a loud noise like a pin or something cameout of the car

Without a chance car now starts with out going forward or back wards…..

Really need the controls og these are fixed if it was just a sensor

Hello Edgar,

If I’m following you correctly, a great deal of transmission fluid leaked out and now the vehicle won’t move in forward or reverse, correct? Have you tried topping off the transmission fluid again?