Unusual sounds other than the low hum coming from the engine are never a good sign, especially high-pitched noises like squealing.

Squealing noises are your engine’s way of telling you that something’s wrong, and you shouldn’t put off a visit to the mechanic. The drive belt is a common culprit of squealing sounds, but what could be the reason behind such noises?

An Overview of Drive Belts

As most people know, the drive belt transfers power from the pulley on the front end of the crankshaft to the A/C compressor, power steering pump (unless the power steering is electric), and alternator. On older vehicles, the radiator fan spins with the water pump and its pulley.

V-Belt

A V-belt has a cross-section tapered in a “V” shape that’s angled at approximately 34 degrees. It can have a flat surface or ridges.

The ridges help make the belt more durable and efficient when running compared to a flat design. Most passenger cars and light commercial vehicles use a V-belt.

Ribbed (Serpentine) Belt

What Causes Squealing Belts?

Belt squeal is typically due to wear, loss of tension, and misalignment. In rare cases, it’s belt design or quality.

Loss of Tension

Operating the starter draws a lot of power from the battery. Because the alternator’s voltage regulation system detects that the battery needs extra charge (and it does right after starting), a loose belt will squeal as the alternator field strength is increased to meet this demand, because alternators require more torque when the charge load is increased.

Loss of tension can be attributed to a worn-out automatic tensioner (see the video below), oil or coolant contamination, or a used-up drive belt.

Misalignment

A slight misalignment in the drive belt system can result in belt chirp, which is the noise produced from belt ribs sliding down one side of the pulley grooves. Misalignment noise generally originates where the pulleys are closest to each other.

Misalignment can either be angular or parallel.

Angular misalignment occurs when the faces of the sheaves don’t form a straight line. Meanwhile, a parallel misalignment can have the sheaves aligned, but their position on the shaft creates a parallel offset.

Leaving misalignment issues in the drive belt system unresolved can result in the following:

- Premature V-belt failure

- Higher belt operating temperature and energy consumption

- Uneven belt wear

- Belt rollover in the sheave groove

- Unbalanced load transfer to one side of the belt

- Increased vehicle vibrations

- Instability problems

Belt Installed Improperly

Belt Tension Measurement

Belt tension should always be within factory specifications. Here are several ways to check the drive belt for proper tension.

Belt Tension Gauge

A belt tension gauge is used to adjust the drive belt tension accordingly. Upon installing a new belt, operate the engine with all accessories running. This will run-in the belt.

Marks on a Tensioner

A lot of tensioners have marks that indicate the normal operating tension range of drive belts. You can check your owner’s manual for more information regarding the tensioner mark’s exact location.

Torque Wrench Reading

Some automakers recommend using a beam-type torque wrench to determine the right amount of torque to rotate the tensioner.

If the torque reading is below factory specifications, the tensioner should be replaced.

Deflection

One way to measure belt tension is to depress the belt between two pulleys that are the farthest apart. The flex or deflection should be 0.5 inches.

Note, however, that this is rarely done, even though there are tools for it, and this is typically more prevalent on belts that are adjusted by moving a pulley or a component. If you overtighten a belt it can destroy some of the components, like the A/C compressor.

Drive Belt Diagnosis

Even if you’re not an experienced DIYer in automotive repair, there are still a couple of methods you can try to diagnose a failing drive belt. Here are some of them.

The Water Spray Trick

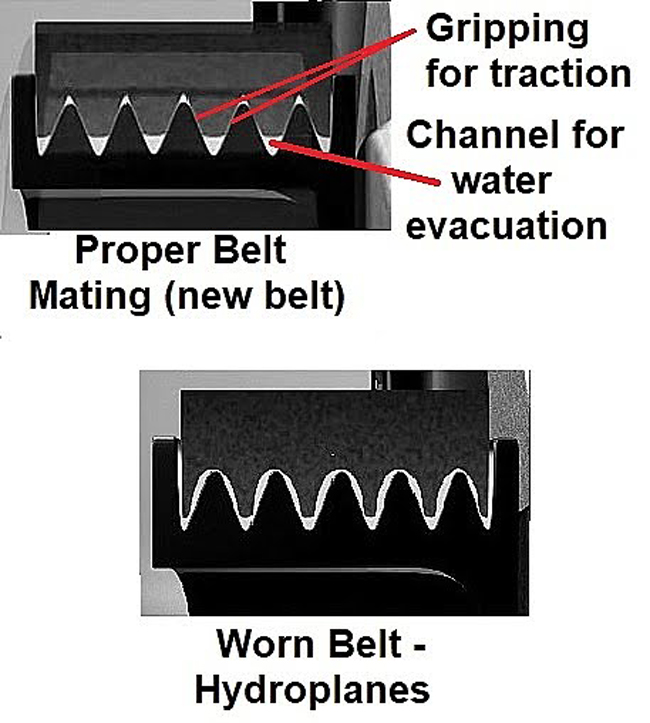

A loose or slipping drive belt can result in low alternator output. It’s possible that the interference angle between the Vs of the belt and pulley has worn out, causing the drive belt to slip and create a squealing sound.

If the noise gets louder when water is sprayed on the belt at the suspected point of noise (usually the shortest belt span between two pulleys when one of them is driven by the back of the belt), it means there’s not enough tension; replace the belt and the tensioner.

If the noise stops briefly after the belt is sprayed with water, it generally points to an alignment problem.

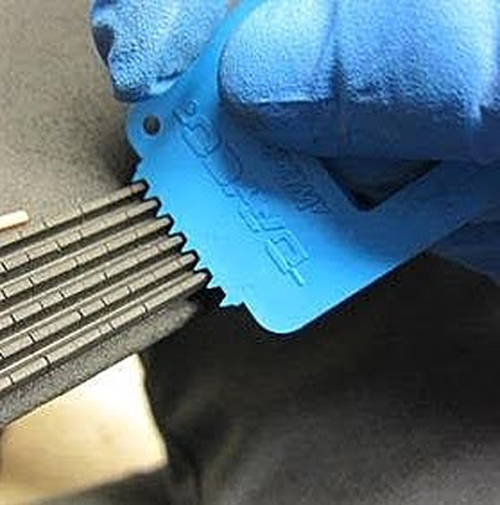

The Hand Cleaner Trick

The hand cleaner trick is another way to determine if the squealing noise is coming from the drive belt.

Sprinkle some grit-type hand cleaner or scouring powder onto the pulley side of the belt while the engine is off. If the belt turns quiet upon starting the engine, then you’ve determined the problem.

How to Stop Belt Squeal

The most fool-proof way to stop a belt squeal is to simply get a new one and a new tensioner if the old tensioner is vibrating when the engine is running.

Drive belts are generally wear-and-tear components that only last for a couple of years. Replacing them every now and then is the only way to maintain your engine’s optimal operation.

You might also want to watch out for noise and wear from the tensioner bearing.

Drive Belt Maintenance

It’s generally recommended to replace all belts every four to seven years. It’s also a good idea to replace any belt that has more than three cracks in any one rib that appears in a three-inch span.

A new drive belt can cost anywhere between $50 and $65, depending on your vehicle’s specifications.

With the proper information and necessary skills, you can replace a worn-out drive belt in the comfort of your garage, helping you save on repair costs.

But if you prefer going to a mechanic to get this kind of job done properly, you could be looking at additional labor fees that can range anywhere between $55 and $75.

Where to Get a High-Quality Drive Belt for Your Vehicle

As mentioned, getting a new drive belt is the easiest way to stop belt squeals. Of course, you’ll need to make sure you get a high-quality replacement belt to ensure it won’t fail like your old part. Fortunately, it’s easy to find one when you shop at CarParts.com.

Our strategically located warehouses across the US ensure fast and efficient shipping. If you place your order before noon, you can expect your package to arrive in as fast as two business days.

Visit our website and enter your ride’s year, make, and model into our vehicle selector to start browsing compatible drive belts. You can then use our search filters to shop according to your preferred brand, price range, and more.

All our products passed stringent testing procedures, so you can rest assured you’re getting the best parts for your ride. They also come with a low-price guarantee, which means you don’t have to break the bank to complete your repairs.

Shop now at CarParts.com to get the best deals on drive belts today!

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.