Level of Difficulty: Advanced

Tools Required: Lift and air tools, Pitman arm puller, Saw, support stands and an assistant

Installed By: OC Motorsports

Install Time: Approximately 5-6 hours

Upon taking our stock 2015 Jeep Rubicon off-road we learned first-hand the advantages of additional ground clearance, wheel travel and increased suspension articulation. After discussing options with Dan Fresh at OC Motorsports we concluded that a 4” lift kit and 35” tires would give our Jeep additional off road capabilities without major sacrifices in on-road ride comfort. We turned to JC Whitney Centennial Suspension Sponsor Rancho to learn more about the latest version of their Jeep lift kits and chose their RS66104 kit in red. We were pleased to discover that Rancho had just launched their new RS5000X, a twin tube shock specifically designed to work with lifted applications. Rancho sent the lift kit and shocks to OC Motorsports for installation. As usual, Rancho has assembled a comprehensive suspension kit with high quality components and quality hardware. Laying out the pieces prior to installation:

As we have spent time in and under the Jeep we have learned about the rugged simplicity of the Jeep’s stock suspension and looked forward to enhancing its already substantial capabilities. Daniel at OC Motorsports was assigned to our project and was very comfortable with the nuances of installing our Rancho kit and has installed hundreds of Jeep lifts. We started at the front of the Jeep and positioned the support stands under the front axle and proceeded with freeing the brake lines from their mounts and loosening the lower shock mounts and sway bar links.

Moving on Daniel loosened the track bar lower shock mount and disconnected the sway bar links and front driveshaft.

With the front spring out the way the front axle is free and supported by the stands. Daniel removed the heat shields to access the upper control arms.

Daniel moved over to the right side and removed the spring and prepared for the install of the lower control arms by lubricating and pressing the Rancho polyurethane bushings and metal sleeves through the bushings.

The Rancho control arms have zerk fittings for periodic greasing to keep the suspension quiet and free from binding.

Moving to the upper control arms Daniel measures the length of the control arms per Rancho’s direction to ensure proper alignment.

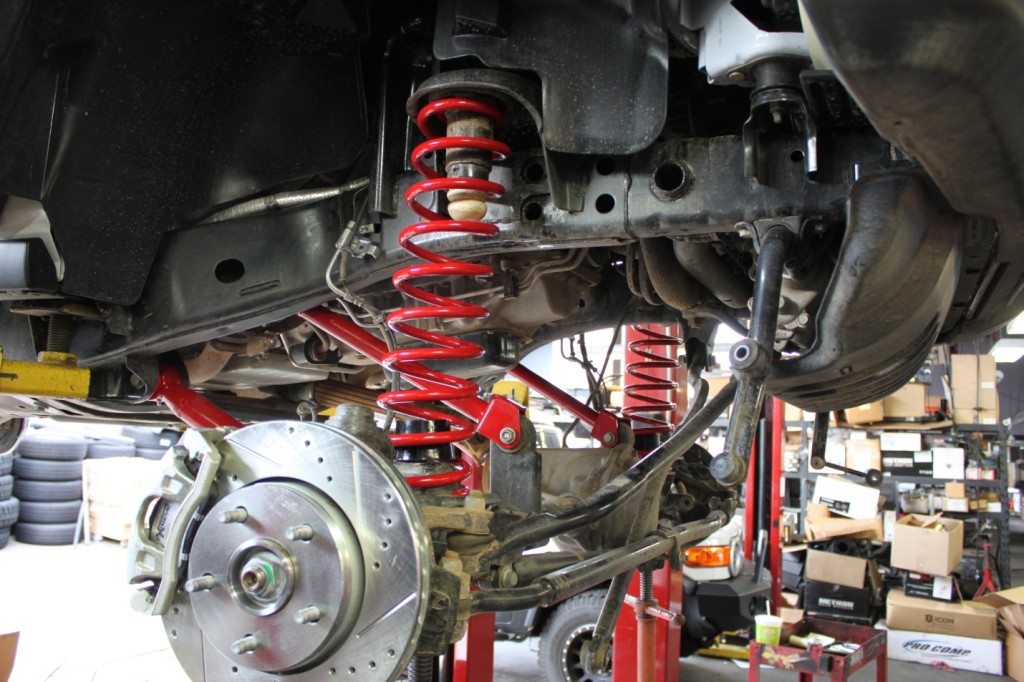

The front axle is coming together as Daniel installed the left and right upper control arms; drilled holes for the new bump stops supplied with the kit and fit the springs.

Next up is the installation of the new pitman arm and track bar bracket to the front axle. Daniel removes the OE arm with the pitman arm puller and installs the Rancho pitman arm onto the steering gear.

With the bracket in place the drag link and track bar are relocated and a strap helps bring the parts into alignment so Daniel can tighten all of the fasteners. Daniel removes the OE sway bar end links then lubricates and installs the supplied bushings and inserts in the Rancho end links.

With all of the steering components in place Daniel installed the new Rancho 5000X shocks, steering stabilizer and dust boots, removed the existing rubber brake lines and replaced them with the new Goodridge braided lines supplied in the Rancho kit. Once the lines are tightened up don’t forget to bleed the brakes before you install your wheels.

Moving to the rear of the Jeep the process is repeated with the support stands in place Daniel removed the brake line and emergency brake brackets, shock mounts and track bar to gain access to the control arms.

Daniel has lubricated and installed the supplied bushings and sleeves into the control arms and installs the lower arms first. Next the Rancho bump stop spacer and track bar adaptor is attached to the rear axle.

The new springs go on next followed by the sway bar mount spacers and shocks. Daniel assembled the upper control arms and threaded the end link to the correct dimension per the Rancho instructions.

Finishing the rear axle, Daniel reattached the track bar to the adaptor and tightened all of the hardware to the Rancho spec.

The last element of the Rancho install is fitting the supplied downpipe to increase clearance between the front driveshaft and exhaust. Daniel measured the exhaust and cut it with a saw to install the pipe-it was a perfect fit.

With all of the Rancho hardware tightened and torqued to spec, Daniel bolted our wheels back on and rolled our newly lifted Jeep off the lift. It looks great and we can’t wait for our next off-road adventure to learn more about how our JK gets along with increased ground clearance and suspension travel. New Weld wheels are part of our plan. Check back soon for a full report and to see how our JK build is coming along.

Brands featured in this episode:

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.