Your vehicle’s coolant needs to run at certain temperatures for the engine to function optimally. Vehicles have a temperature gauge on their gauge cluster to make it easier to keep track of coolant temperatures. These gauges indicate when your engine is overheating. Today, we’ll be looking at car temperature gauges, the different types, and how they compare to each other.

What Is a Car Temperature Gauge?

Your vehicle’s temperature gauge is a part of its emissions control system. The gauge measures engine coolant temperatures, relaying the information to you through the gauge cluster. Engine coolant absorbs heat from the engine’s cylinders, cooling the engine in the process.

The coolant absorbs heat from the head and cylinder walls by conduction, then by convection it carries and releases this heat through the radiator. Both mechanical and electric temperature gauges act as thermometers for the coolant, indicating when the engine coolant is running too hot. Car temperature gauges are sometimes called water temperature gauges despite the fact that they measure coolant temperature.

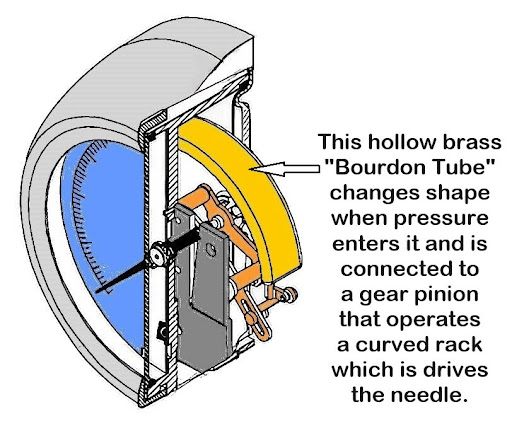

Mechanical Temperature Gauges Explained

Mechanical temperature gauges work by detecting changes in engine pressure, which fluctuates depending on the engine’s internal temperature.

Mechanical Temperature Gauge Benefits

Mechanical temperature gauges don’t need electricity to work. You don’t need to worry too much about matching up sending units, you only need to screw the probe into a coolant passage.

Mechanical gauges also deliver accurate readings even when the vehicle is off. When conducting repairs, this makes it especially easy to check how the heat in the engine dissipates while the engine isn’t running.

Mechanical Temperature Gauge Drawbacks

Unfortunately, mechanical temperature gauges are a little more complex to install. You need to route the capillary tube that the gauge attaches to through the engine and dash. There can’t be any sharp bends or you risk damaging the tube either during installation or over time. In addition, you need to keep the tube away from header tubes and other heat sources that might affect the gauge’s accuracy. The mechanical gauge is also larger than an electric temperature gauge sending unit, making plugging it into the engine’s water jacket impossible.

Electric Temperature Gauges Explained

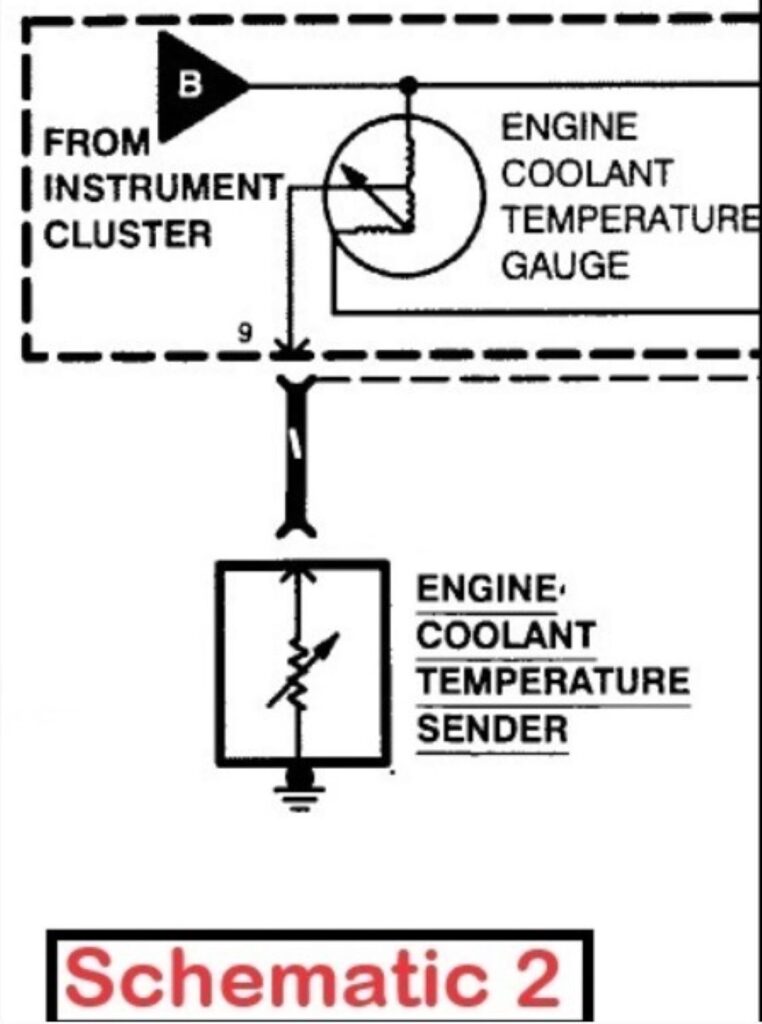

Electric temperature gauges are made up of a gauge and a sending unit with a wire connecting the two parts. Where you place the sending unit typically depends on its design. Some have the sending unit go into one of the engine’s coolant passages, where it sends its temperature readings to the gauge through the connecting wire.

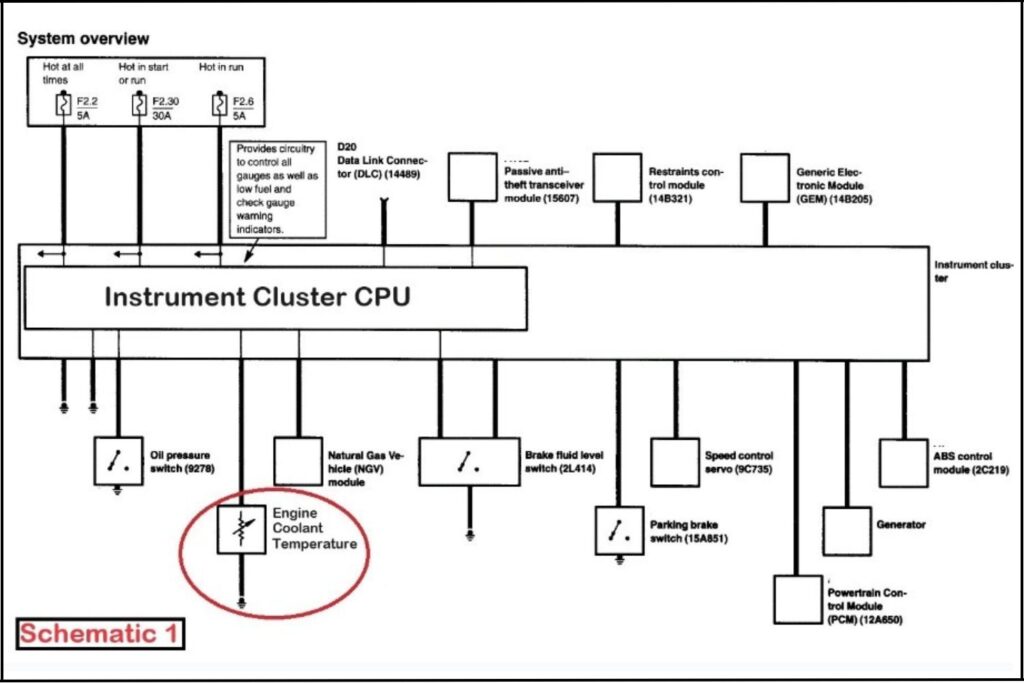

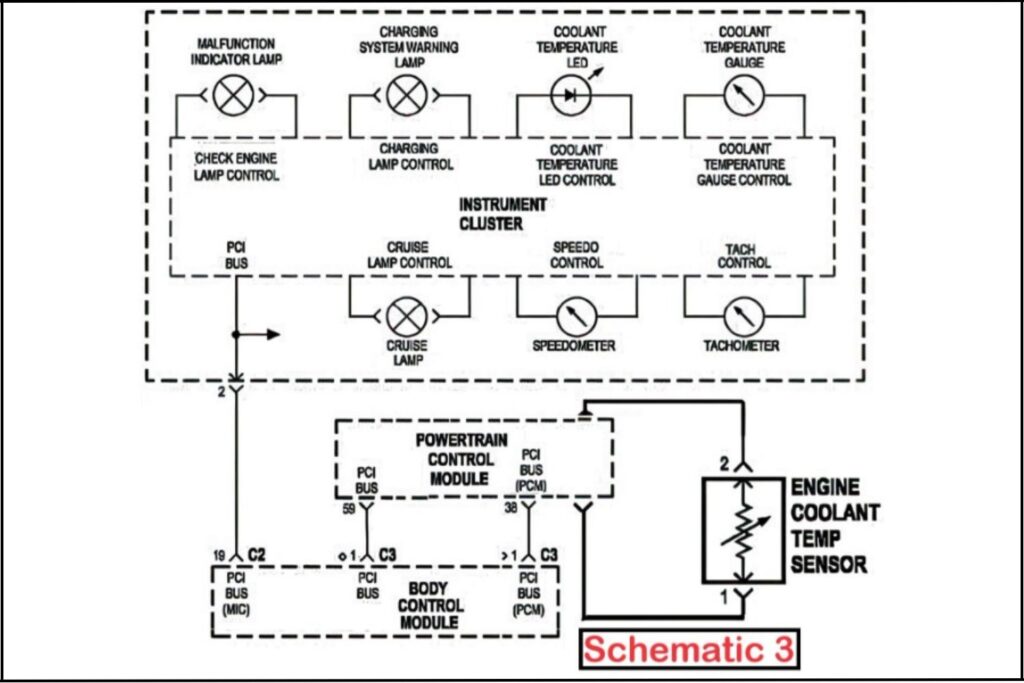

The following schematics show how OEM coolant temperature gauges are wired. Schematic 2 is the simplest, with the sender wired directly to the gauge unit.

The sending unit uses a thermal-sensitive electrical resistor called a thermistor. The thermistor’s electrical resistance changes as the temperature around it fluctuates, and the gauge reads these changes accordingly. The gauge interprets the information into a temperature reading to display on its face.

Electric Temperature Gauge Benefits

Because electric temperature gauges use an electric signal instead of a capillary tube to relay temperature info back and forth between the gauge and the sending unit in the engine coolant passage or water jacket, it’s much easier to route the wire between the two. You don’t need to worry about bending the wire into sharp corners or near other heat sources. Electric temperature gauges also have more customization options and are highly precise and accurate.

Electric Temperature Gauge Drawbacks

Electric temperature gauges rely on resistance, meaning if anything happens to their electrical connections, it will likely affect their readings. Grounding or continuity issues between the engine and the gauge can also cause erratic readings because the sending units in electric gauges often rely on a chassis or engine ground.

Mechanical vs. Electric Temperature Gauge Comparison

When comparing mechanical vs. electrical temp gauges, you’ll need to consider different factors.

Customizability

As mentioned earlier, there are more styles of electric gauges than mechanical gauges, meaning you have more options if you want a gauge with different colors or display styles.

Connection Style

The fact that electric gauges connect to a sending unit via electricity makes them incredibly accurate, allowing electric temperature gauges to show reliable and consistent real-time readings with minimal fluctuations. Mechanical gauges, on the other hand, link directly to the coolant passage through the capillary tube. The direct link allows these gauges to respond faster and provide instant readings.

Installation

While certain steps to installing mechanical gauges are simpler, it’s ultimately easier to install an electric gauge thanks to its connection style and electrical system compatibility. You might still need to make additional modifications when installing a mechanical gauge in vehicles that didn’t originally have one. Neither process is for a DIY beginner.

Pricing and Reliability

Thanks to their complexity, electric gauges tend to be more expensive than mechanical gauges. Electric temperature gauges are also more susceptible to electrical system malfunctions, but they’re often more accurate and precise. Mechanical gauges, while incredibly durable, tend to suffer from mechanical wear over time, losing accuracy as they age.

Tips for Testing Temperature Gauges

If you want to test your temperature gauges, you can use a boiling pot of water. On a mechanical gauge, you’ll need to place the temperature probe into the pot while the gauge and the capillary tube sit away from the heat. The gauge should show 212 degrees fahrenheit when the water begins boiling.

We don’t recommend testing an electric temperature gauge yourself if you’re unfamiliar with electronic testing in general.

Ultimately, the choice between automotive temperature gauge types depends on your preferences. If you want a reliable, easy-to-install gauge, go for an electric gauge. For a more affordable, durable gauge, purchase a mechanical gauge.

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.