Inside Your Engine: Everything You Need to Know About Engine Sensors

Cars are equipped with many different sensors located around the vehicle to monitor certain functions. Many sensors are located in the engine, with each sensor monitoring specific engine parameters that are fed to the engine control unit (ECU). The ECU makes changes to engine operation based on the readings to make sure the engine is working as efficiently as possible.

But what does each car sensor do? How do they function? In this article, we’ll tackle seven of the most important engine sensors. We’ll explain the function of each sensor and the symptoms to look out for if the sensor is malfunctioning.

Oxygen Sensor

Function

The oxygen sensor monitors how much unburnt oxygen is present in the exhaust gases. This is done to gauge whether or not the engine is efficiently combusting fuel. If the engine leaves a lot of unburnt oxygen, then it means that the engine is running lean, which means more fuel can be included in the mixture. If the engine leaves behind too little oxygen, it means the engine is running rich. Oxygen sensors are very important in modern cars because as load, altitude, and humidity change, the ECU doesn’t always know what fuel mix is right. Oxygen sensors let the ECU correctly gauge the fuel mix.

Location

Most vehicles have two oxygen sensors located in the exhaust. One is mounted before the catalytic converter and one is mounted after the catalytic converter.

Symptoms of a Faulty Oxygen Sensor

Like many parts in your engine, your check engine light turning on could be a sign that you need to replace your oxygen sensor. Other symptoms include your vehicle having a rough idle, misfires, lack of power, and stalling. These symptoms are very noticeable and could damage your engine in the long run if you continue to use your vehicle without replacing your oxygen sensor.

A faulty oxygen sensor will also hurt your vehicle’s fuel efficiency. The Environmental Protection Agency says that simply replacing broken oxygen sensors could improve fuel economy by as much as 40%. Aside from poor engine performance, your vehicle is also likely to fail an emissions test if you take one with a faulty oxygen sensor.

For more information about the symptoms of a bad O2 sensor, click here.

Lifespan

The sensor is built to last as long as your car but can sometimes fail prematurely.

Related OBD-II Trouble Codes

Mass Air Flow Sensor

Function

The mass airflow sensor (MAF) is used to measure how much air enters the engine. A typical MAF sensor measures airflow by heating a small wire with electricity and then passing a small amount of air around the wire. The more air flows, the more the wire cools down, so more electrical current is needed to keep it hot. Since the amount of electrical current needed to keep it hot is proportional to the amount of airflow, the amount of electrical current can give the ECU an approximation of how much air is passing through.

This information is important for the ECU to correctly balance and deliver the correct amount of fuel to the engine. The end goal is to deliver an optimal fuel to air ratio to the combustion chamber.

Location

The MAF sensor is typically located after the air filter and before the intake manifold of the engine.

Symptoms of a Faulty Mass Air Flow Sensor

Dirty or faulty mass air flow sensors can give the ECU inaccurate readings. Because of the incorrect airflow readings, the engine won’t be able to operate at the optimal fuel to air ratio. It will exhibit symptoms such as difficulty starting, stalling, poor acceleration, rough idle, poor fuel economy, and black exhaust smoke. The vehicle’s check engine light might also light up.

The vehicle’s computer can also sometimes use the MAF sensor to determine shift points in an automatic transmission, so a problem with the MAF sensor may alter the transmission’s shifting pattern. Your vehicle could either shift earlier or later than usual in its rev range.

For more information about the symptoms of a bad MAF sensor, click here.

Lifespan

The sensor is built to last as long as your car but can sometimes fail prematurely.

Related OBD-II Trouble Codes

Oil Pressure Sensor

Function

Oil needs to be channeled into the engine’s many nooks and crannies for it to be properly lubricated enough to function correctly. Without the aid of pressurized engine oil, the engine can run into severe issues, such as overheating and engine damage. An oil pressure sensor is important as it will help warn you if your vehicle is losing the valuable oil pressure it needs to function.

The oil pressure sensor sends signals to the oil pressure light on your dashboard. If oil pressure levels are either too high or too low, then it will light up to warn you.

Location

The oil pressure sensor is typically located between the oil filter and oil pan, at the bottom right side of your engine.

Symptoms of a Faulty Oil Pressure Sensor

You won’t be able to determine the oil pressure in your engine without a functioning pressure sensor light. But if your oil pressure sensor lights up, how do you know whether the light is caused by a broken oil pressure sensor or problematic oil pressure levels? To determine the root cause of the problem, a professional automotive technician can check the engine’s actual oil pressure with a mechanical gauge.

For more information about the symptoms of a bad oil pressure sensor, click here.

Lifespan

The sensor is built to last as long as your car but can sometimes fail prematurely.

Related OBD-II Trouble Codes

Throttle Position Sensor

Function

The throttle valve controls how much air is able to enter the engine’s intake manifold. Throttle position sensors (TPS) are supposed to monitor how far the throttle valve is open. The throttle valve’s opening is usually proportional to how far the accelerator pedal has been pushed by the driver. Like many other sensors in the engine, the TPS has an important role in determining the correct fuel to air ratio in the engine. The information that the TPS provides may also be used by other systems in the vehicle, such as traction control, the anti-lock braking system, and cruise control.

Location

The TPS is typically directly attached to the throttle valve, located at the top of the engine.

Symptoms of a Faulty Throttle Position Sensor

A faulty TPS can cause misfires and stalling. On vehicles with electronic throttle control, a bad TPS may also cause the vehicle to enter limp mode, resulting in a loss of power. Luckily, the check engine light is designed to light up when the TPS goes bad.

For more information about the symptoms of a bad TPS, click here.

Lifespan

The sensor is built to last as long as your car but can sometimes fail prematurely.

Related OBD-II Trouble Codes

Coolant Temperature Sensor

Function

The engine coolant temperature sensor (ECTS or CTS) is used to measure the temperature of the coolant or antifreeze circulating in the engine and cooling system. Measuring the temperature of the coolant gives information on how much heat the engine is producing and also gives an idea of how much heat the cooling system is able to redirect away from the engine.

The ECTS can detect temperature changes by calculating the voltage that can pass through it. The resistance of the sensor depends on the temperature. When the coolant is hot, the voltage that passes through the ECTS will have less resistance. The ECU uses the temperature reading to control a variety of functions, such as ignition timing and the speed of the radiator’s cooling fan.

Location

There is usually one ECT sensor located somewhere on the engine. There may also be a secondary ECT sensor in the radiator.

Symptoms

A faulty sensor can give off coolant temperature readings that may either be higher or lower than usual. As a result of the wrong engine temperature readings, the engine could perform poorly or have poor fuel economy. A cool reading is an indication for the ECU to use a richer fuel to air ratio, while a lower reading will lead to a leaner mix. A rich fuel to air ratio can cause black smoke to come out of your exhaust. A faulty coolant temperature sensor can cause your check engine light to come on or your car to overheat.

Lifespan

The sensor is built to last as long as your car but can sometimes fail prematurely.

Related OBD-II Trouble Codes

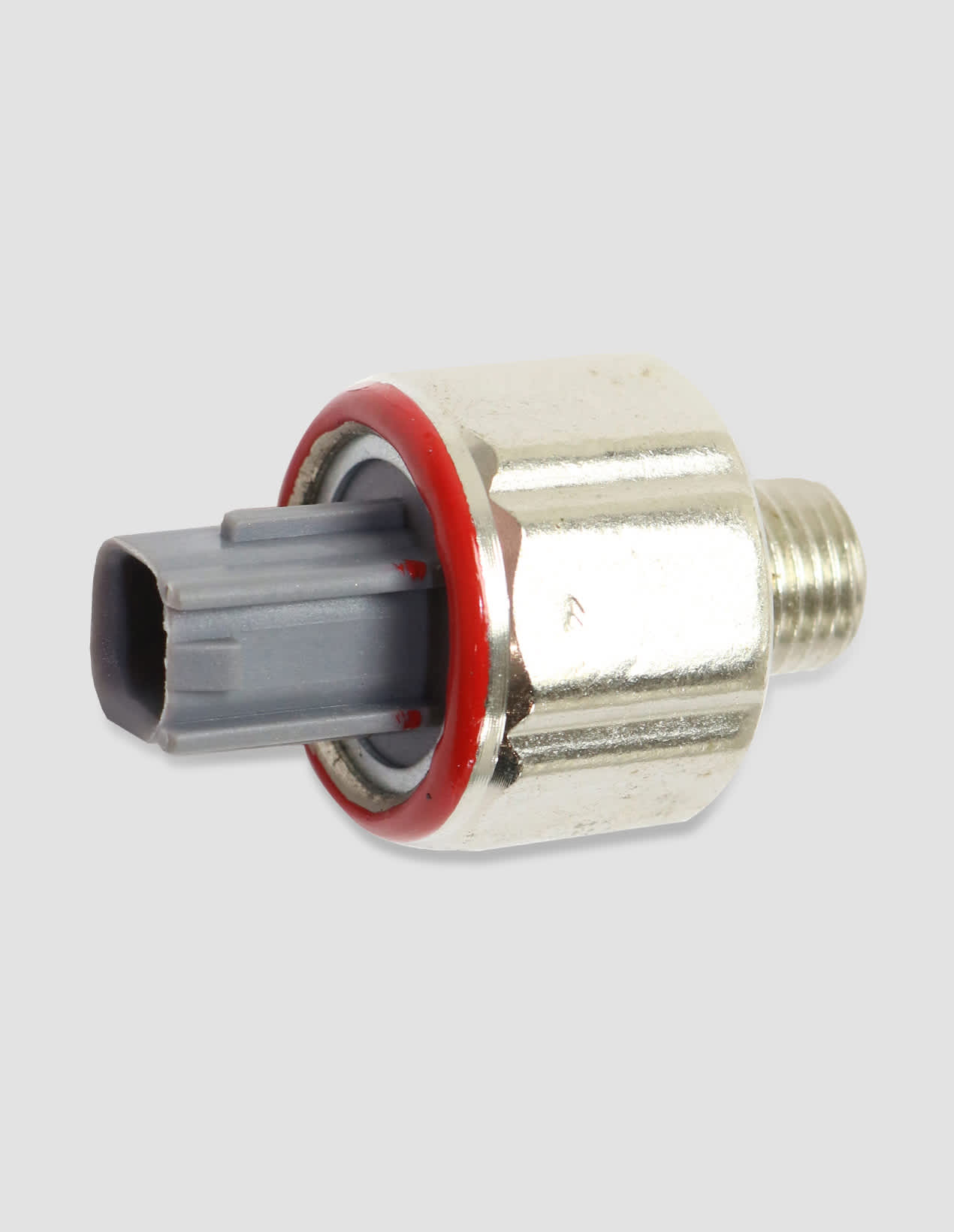

Knock Sensor

Function

Engine knock (detonation) happens as a result of abnormal combustion inside of the engine. Knock can be destructive to your engine. Knock sensors are designed to detect the characteristic knock or ping noises caused by abnormal combustion by picking up the distinct vibrations they create. Knock sensors are also able to identify engine knock so that the ECU can retard ignition timing until the knock diminishes.

Location

The knock sensor is attached to the outside of the engine block, but it can also be located underneath the intake manifold.

Symptoms of a Faulty Knock Sensor

Without a properly functioning knock sensor, your ECU won’t be able to make the adjustments necessary to stop engine knock from happening. As a result, you may hear the characteristic knocking or pinging noises associated with engine knock. Additionally, your vehicle’s ability to accelerate may be diminished. The check engine light will also likely turn on. If engine knock keeps happening as a result of a faulty knock sensor, important internal engine components could be damaged. Your engine could even fail catastrophically if you continue to use your vehicle with a faulty knock sensor.

For more information about the symptoms of a bad knock sensor, click here.

Lifespan

The sensor is built to last as long as your car but can sometimes fail prematurely.

Related OBD-II Trouble Codes

Crankshaft Position Sensor / Camshaft Position Sensor

Function

The crankshaft and camshaft position sensors detect the current rotation position and speed of the crankshaft and camshaft respectively and they send this information to the ECU. The crankshaft is responsible for converting the linear motion of the pistons into the rotational force needed to propel the vehicle, while the camshaft is responsible for the opening and closing of each of the engine’s valves. They must work in sync for the engine to function. Crankshaft and camshaft position sensors rely on a reluctor ring that has teeth. As the two shafts rotate, the teeth on the reluctor ring pass close to the tip of the sensor, where they’re detected using magnets. Since one or more teeth are missing to provide a reference point, each tip will correspond to a specific crankshaft or camshaft position for the ECU.

Location

The crankshaft position sensor will often be located close to the main pulley, at the transmission bell housing, or at the cylinder block.

Symptoms of a Faulty Crankshaft Position Sensor/Camshaft Position Sensor

If your crankshaft position sensor has already failed, then your engine may not start. The same is usually true for the camshaft position sensor. But if they’re only starting to fail, then it might result in an inconsistent signal being sent to your ECU. As a result, your engine might shut off suddenly, or you might have difficulty starting your vehicle. Additionally, a faulty sensor can cause sudden stalls, inconsistent acceleration, and engine misfires. The car will likely jerk, surge, and vibrate as a result of the improper amount of fuel being injected into the engine, since the ECU is getting incorrect information about the camshaft’s position. The check engine light in your dashboard will also light up.

For more information about the symptoms of a bad CKP, click here.

Lifespan

The sensor is built to last as long as your car but can sometimes fail prematurely.

Related OBD-II Trouble Codes

When your engine sensors fail, they tend to create very similar engine and performance-related symptoms. Deciphering which sensor is faulty just through symptoms alone is difficult. That’s why you should visit a mechanic if you experience engine-related issues. They can check your vehicle’s onboard diagnostics to narrow down which part needs to be replaced, or they can manually inspect each part. Having your vehicle checked as soon as you experience these issues is vital, because prolonged usage with any faulty sensor can lead to engine damage, which is notoriously expensive to repair.

Decades of automotive innovation made all these sensors standard in all vehicles, so engines can meet modern standards of reliability and efficiency. Engine sensors are one of the reasons why modern engines are so much more efficient and reliable than the engines from a few decades ago. They’re the product of engineers paying close attention to the process of producing power, so much so that they’ve turned a seemingly chaotic and violent process into a delicate art.

About CarParts.com

For over 20 years, CarParts.com has been a leader in the e-commerce automotive aftermarket, providing collision, engine, and performance parts and accessories. With over 50 million parts delivered, we've helped everyday drivers across the contiguous United States find the right parts to keep their vehicles on the road.

With a focus on the end-to-end customer experience, we've designed our website and sourcing network to simplify the way drivers get the parts they need. Our vehicle selector and easy-to-navigate, mobile-friendly website offer customers guaranteed fitment and a convenient online shopping experience. And with our own wide distribution network, we bring the very best brands and manufacturers directly to consumer hands, cutting out all the brick-and-mortar supply chain costs to provide quality parts at a discount for our loyal customers. Combined with our 60-day return policy and satisfaction guarantee, CarParts.com makes it simple for customers to get parts delivered straight to their door. CarParts.com is headquartered in Torrance, California.