Cylinder compression plays a huge part in how well your engine operates. If one or more cylinders are affected by compression loss, you can expect problems to arise, including engine misfires and poor vehicle performance.

If you think your vehicle isn’t running like it used to, it might be time to conduct a leakdown test and identify a possible air leak.

Lucky for you, a cylinder leakdown test is a fairly straightforward process.

What Is a Cylinder Leakdown Test?

A cylinder leakdown test is a procedure used to determine the percentage of compression loss due to components like piston rings, head gaskets, and valves.

Also referred to as a cylinder leakage test, this procedure involves injecting air under pressure into the cylinders one at a time. The air is injected into the cylinder/s via a cylinder leakage gauge that goes into the spark plug hole.

A leakdown test is typically done after performing a compression test that revealed low cylinder compression.

A compression test will find a cylinder with low compression but cannot be used to determine leak paths.

Cylinder Pressure

Cylinder pressure containment is necessary for a cylinder to function properly. The compression stroke is the activity that follows the intake stroke. The cylinder being tested must be on the compression stroke with the piston at the top of its travel (TDC) for this test to be administered accurately.

A Close Look at the Leakdown Tester

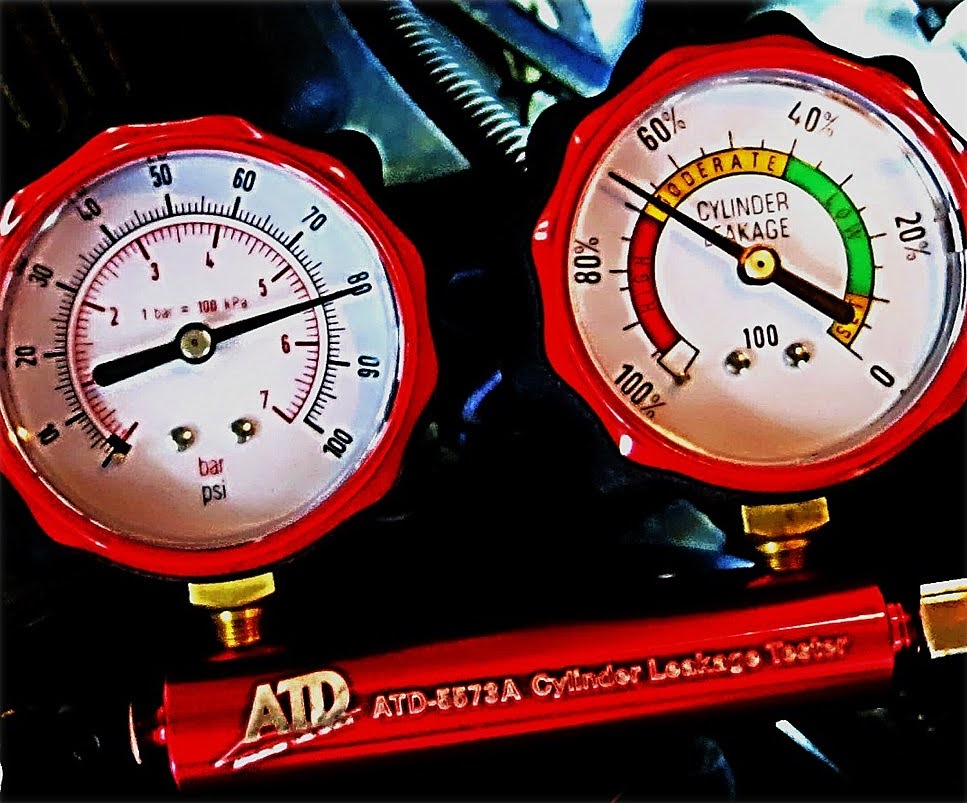

Cylinder leakdown testers can either have one or two gauges. A single-gauge unit might seem easier to operate than a dual-gauge type, but the former will require you to carefully pay attention to the inlet pressure while conducting the leakage test.

Meanwhile, the dual-gauge or twin-gauge leakdown tester lets the user read the inlet air pressure on one gauge and the percentage of cylinder leakage on the other.

All leakdown testers have the same objective, but keep in mind that they’re not created equal and might not have the same readings. What’s important is that the inlet air pressure stays the same regardless of the type of gauge you’re using.

How to Do a Leakdown Test

A leakdown test is a rather simple diagnostic procedure that you can do from your garage 一 provided that you have the right tools and information.

Here are the generic steps for conducting a leakdown test.

Step 1: Make sure the engine is at operating temperature. This means that the upper radiator hose should be hot and pressurized.

Step 2: Leave all the spark plugs in except for the cylinder you’re testing.

Step 3: Confirm that the cylinder being tested is at TDC of the compression stroke. This sounds easier than it is, but you have to know how to make it happen, particularly on cylinders besides #1 and its companion. Only cylinder #1 is marked on engines that even have marks on the balancer, and some don’t. You have to know the firing order and be able to tell how many degrees you’re turning the crank between compression events. The piston is at TDC during the compression and exhaust strokes and you must have it at the top on the compression stroke of the cylinder you’re testing. Most of the time, only suspect cylinders will be tested rather than all of them.

Step 4: Install the air-fitting adapter into the spark plug hole. Use a breaker bar or ratchet and socket for the crank nut.

Step 5: Make sure the leakdown tester’s gauge is reading zero. Then, calibrate the cylinder unit leakage unit as per the manufacturer’s instructions.

Step 6: Inject air into the cylinders one at a time, and rotate the engine by firing order to test each cylinder at TDC on the compression stroke. Gently rock the piston around TDC to ensure the rings are seated.

Step 7: Record your leakdown percentage and repeat the entire procedure until all the cylinders have been tested.

Step 8: Evaluate the results:

- Less than 10% leakage: good

- Less than 20% leakage: acceptable

- Less than 30% leakage: poor

- More than 30% leakage: definite problem

Note: If the leakage readings are unacceptably high, repeat the test. Also, make sure that the cylinder being tested is at the top dead center on the compression stroke.

Leak Paths

Here’s how to check the source of air leakage.

- Air escaping from the oil filler cap indicates worn or broken piston rings or a problem with the piston. Note that some leakage past the piston rings is normal.

- Air bubbling out of the radiator indicates a blown head gasket or cracked cylinder head.

- Air coming out of the throttle body or air inlet (for fuel-injection-equipped engines) indicates a defective intake valve.

- Air coming out of the tailpipe points to a defective exhaust valve.

Leakdown Test FAQs

Below are the answers to the frequently asked questions (FAQs) about cylinder leakdown tests.

What is the difference between a leakdown test and a compression test?

A leakdown test is conducted to determine whether or not the engine can hold pressure. A compression test, on the other hand, is used to determine how much pressure the engine makes.

A compression test can help you determine whether or not all cylinders have equal compression. Compression test results can inform you whether the intake or exhaust valve, piston rings, or cylinder head gasket is causing compression loss.

What is the PSI for a leakdown test?

Compressed air with approximately 100 PSI is used when conducting a leakdown test.

How much cylinder leakage is acceptable?

There’s no such thing as a perfectly sealed engine. At some point, all engines lose compression.

Generally, a five to 10% compression loss indicates that the engine is in great condition.

Meanwhile, a compression loss of 15% to 20% isn’t exactly indicative of major engine problems, but it’s enough to let you know that you need to find the source of the leak right away.

A compression loss of 30% or more usually means there are major engine problems that might require an overhaul.

Does the engine need to be warm before conducting a leakdown test?

Warming up the engine before conducting a leakdown test causes the rings to expand and create a tighter seal. However, it’s still possible to conduct a leakdown test while the engine is still cold.

Failed A Leakdown Test? Get Replacement Engine Components Online

Your engine might not show any symptoms, but failing a leakdown test is never a good sign for your engine. The engine’s cylinder needs to be sealed during combustion, or else your engine might develop problems like misfires. If you find your engine’s faulty component, you shouldn’t hesitate to replace it immediately. Just know that getting replacement engine components is easy and convenient here at CarParts.com.

CarParts.com is a one-stop shop for a wide range of engine components including piston rings, head gaskets, and valves, to name a few. Our parts are sourced from only the best manufacturers in the industry, ensuring quality. Our strategically located warehouses also mean we can ship your order to your doorstep in as fast as two business days.

Get your engine performing properly when you purchase piston rings, head gaskets, intake valves, and exhaust valves. Order engine parts from CarParts.com today!

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.