Engines with a twin-cam configuration have been around since the beginning of the 1900s. But what exactly does a twin-cam engine do, and how does it differ from an overhead valve setup?

Double Camshaft Equals Double Power

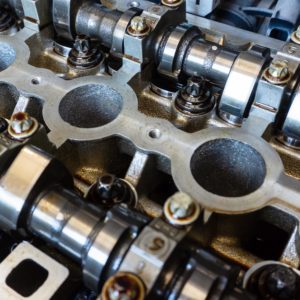

A twin-cam configuration, also known as the double overhead camshaft (DOHC) setup, uses two camshafts per cylinder bank.

In this configuration, one camshaft will operate the intake valves and the other will be in charge of the exhaust valves.

In this setup, the overhead camshafts are belt-driven or chain-driven from the crankshaft and typically located in the cylinder heads. Because there are two camshafts doing separate jobs, the engine can breathe better and burn cleaner.

A twin-cam engine can produce more horsepower with a smaller engine volume, making it more efficient than a single overhead camshaft (SOHC) engine.

The Basics of Twin-Cam Engine Operation

We’ve already established that a twin cam can produce more horsepower than an SOHC engine. But how exactly is that possible?

An engine with more than one camshaft can help create better windstream, resulting in a smooth ride.

It can also have improved valve timing, which is crucial in engine performance and efficiency. This is possible because there are disengaged shafts for the intake and exhaust valves.

Disadvantages of a Twin Cam Engine

Although twin cams are highly efficient setups, they also come with a couple of disadvantages.

These engines are more complex than cam in-block plans. They have complicated chain or timing belt systems, which can be expensive to maintain and produce.

This type of engine is also heavier and taller compared to an SOHC setup.

Overhead Camshaft vs. Overhead Valve Engines: What’s the Difference?

Overhead camshaft (OHC) engines have their cams mounted on the cylinder head above the valves. Most engines today have two overhead camshafts that interact with valves or special arms.

Meanwhile, overhead valve (OHV) engines have only one camshaft on the engine block. In this setup, the camshaft lobes activate rocker arms via push rods and lifters in the cylinder head every time the camshaft rotates.

In the overhead valve engine setup, the camshaft lobes activate rocker arms via push rods and lifters in the cylinder head every time the camshaft rotates.

–Anthony Harlin, ASE Certified Master Automobile Technician

OHV configurations are less common than OHC, but you might find a few of them in pickup trucks or full-size SUVs with V-type engines.

A Brief History of Twin Cam Engines

Peugeot was no stranger to pioneering automotive inventions. Aside from the horseless carriage, solid rubber tires, and air-filled tires, the French automaker was also responsible for developing twin-cam engines.

The automaker hired a Swiss engineer named Ernest Henry to design a new engine for 1912. Henry, along with three factory race car drivers named Jules Goux, Georges Boillot, and Paul Zuccarelli, worked on a race car project that sought to rival the design philosophies of Bugatti.

The team eliminated rocker arms and added two camshafts per cylinder bank in an attempt to produce a high-revving engine that’s more powerful than other engines of the same size.

The use of two lighter valves and separate camshafts for the intake and exhaust valves also came from Henry’s calculations that the engine can generate more power if the volume of air-fuel mixture that enters the cylinders can be greater.

Peugeot L76: A Glimpse of the Future

The 1912 Peugeot L76 was the first vehicle equipped with a successful dual overhead camshaft engine.

The speedster won its first race during the 1912 French Grand Prix which was followed by the Indianapolis 500 the following year.

The L76 reached a top speed of 114 mph, which was 15 mph faster than Bugatti’s race car. Shafts and bevel gears operated the camshafts on the L76, accompanied by four valves for each of the four cylinders. Itss engine had a maximum output of 148 hp at 2,200 rpm.

By the 1950s, automakers did the same thing with their respective vehicles, using twin cams in affordable production cars.

Henry and his team were able to create a 7.6-liter inline four-cylinder engine with dual overhead camshafts.

Understanding Camshaft Operation

To have a better understanding of how a twin cam is able to generate more power, it’s important to know the basics of camshaft operation.

The camshaft opens the valves through its lobes. The lobes open the valve against the force of the valve springs.

Driven by timing gears, chains, and belts, the camshaft can also operate the mechanical fuel pump, oil pump, and distributor.

As the camshaft lobe pushes the lifter upward, the camshaft produces a forward twisting force, resulting in an alternating torsion force (forward then backward) at each lobe.

The camshaft also moves lengthwise during engine operation. To control the shaft end thrust, the camshaft uses a thrust plate between the camshaft drive gear or sprocket and a flange.

Camshaft and Cam Timing Specifications

A camshaft must be placed on V-blocks to check for straightness, and a dial indicator is used to measure the cam bearings for runout.

The maximum total indicator runout (TIR) of a camshaft should be less than 0.002 in.

The camshaft lobe height should also be measured to verify the camshaft that’s installed in the engine. This is typically done using a dial indicator and rotating the engine to compare factory specifications.

According to the Society of Automotive Engineers (SAE), all valve events must be measured at 0.006 in. (0.15mm) valve lift.

Cam timing specifications are stated in terms of the angle of the crankshaft in relation to top dead center (TDC) or bottom dead center (BDC) when the valves open and close.

The intake valve should open slightly before the piston reaches TDC to ensure that the valve is fully open when the piston travels downward on the intake stroke.

Meanwhile, the exhaust valve should open as the piston is traveling down on the power stroke to release combustion pressure.

Where to Get New Camshafts for Your Vehicle

When it’s time to repair your twin cam configuration, you’ll need a high-quality camshaft to ensure the setup works as intended. Thankfully, CarParts.com has an array of auto parts that fit your vehicle.

Online shopping has never been easier thanks to our website’s user-friendly design. Everything you’ll need is one click away, meaning you can browse our catalog and order using your mobile devices.

We also have a built-in vehicle selector to ensure the camshaft you ordered fits your ride’s specifications. You’ll only need to input your vehicle’s year, make, and model to filter out the selection.

Shop for a new camshaft on our website, and expect your order to arrive in a matter of days!

Any information provided on this Website is for informational purposes only and is not intended to replace consultation with a professional mechanic. The accuracy and timeliness of the information may change from the time of publication.

Nothing in this article says anything about the reason for twin overhead cams. As per an explanation I got from a Cosworth engineer. with twin cams you can lay the valves over with an angle between them of about 80 degrees. This creates the shortest and straightest ports for the best breathing at higher RPM. An example of this would be the straight six Jaguar engine. It also figures into the Chrysler Hemi engine of drag race fame. Due to the space required, many car engines bring the valves back to shallower angles for better fitment into an engine compartment,losing some of the breathing of the engine. Another good example of an overhead cam engine would be the Offenhauser of Indianapolis fame from the 30’s to the late 70’s.